Samun Babban Ingantacciyar Haƙori-Ta Haƙori na Manyan Gears tare da Dumamawa Induction

A cikin masana'antun masana'antu, manyan gears suna taka muhimmiyar rawa a aikace-aikace daban-daban kamar injina masu nauyi, injin turbin iska, da kayan masana'antu. Don tabbatar da dorewa da aikin su, yana da mahimmanci don amfani da tsari mai ƙarfi ga haƙoran gear. Ɗaya daga cikin ingantattun hanyoyin don cimma taurin haƙori-da-haƙori a cikin manyan kayan aiki shine ta dumama shigar.

Ƙarƙashin ƙarewa tsari ne da ke amfani da shigar da wutar lantarki don dumama saman haƙoran gear cikin sauri. Ta hanyar amfani da babban juzu'i mai jujjuya halin yanzu zuwa nada, ana samar da filin maganadisu, wanda ke haifar da igiyoyin ruwa a saman haƙoran gear. Waɗannan igiyoyin igiyar ruwa suna haifar da dumama da ke cikin gida, suna ba da izini daidai da taurin kowane haƙori.

Taurin haƙori ta haƙori ta amfani da dumama shigar da ita yana ba da fa'idodi da yawa akan sauran hanyoyin taurin. Da fari dai, yana tabbatar da rarraba taurin iri ɗaya a cikin haƙoran gear, yana haifar da ingantacciyar juriya da ɗaukar nauyi. Wannan yana da mahimmanci musamman ga manyan ginshiƙan da ke fuskantar nauyi masu nauyi da matsananciyar yanayin aiki.

Na biyu, dumama shigar da ke ba da damar ɗorawa zaɓaɓɓu, ma'ana kawai haƙoran gear ne masu zafi, yayin da sauran kayan aikin ba su da wani tasiri. Wannan yana rage haɗarin murdiya ko warping, wanda zai iya faruwa tare da wasu hanyoyin magance zafi waɗanda suka haɗa da dumama dukkan kayan aiki. Madaidaicin iko akan tsarin dumama yana ba da damar yin taurin da aka yi niyya, yana haifar da inganci mai inganci, na'ura mai ƙarfi.

Ƙarfafa ƙora na kananan-, matsakaita, da manya-manyan gears ana yin su ta amfani da dabarar haƙori ta haƙori ko hanyar kewayawa. Ya danganta da girman gear, ƙirar taurin da ake buƙata da lissafin lissafi, ana shigar da kayan aiki taurare ta hanyar kewaye duka kayan tare da nada (abin da ake kira " hardening of gears "), ko don manyan gears, dumama su "hakori-da-haƙori" , inda za'a iya samun sakamako mai mahimmanci na hardening, kodayake tsarin yana da hankali sosai.

Haƙori-da-Haƙori taurin manyan kayan aiki

Hanyar haƙori-da-haƙori za a iya yi ta hanyoyi daban-daban guda biyu:

"Tip-by-tip" yana aiki da yanayin dumama harbi ɗaya ko yanayin dubawa, inductor yana kewaye jikin haƙori ɗaya. Ana amfani da wannan hanya da wuya saboda baya samar da gajiya da ake buƙata da ƙarfin tasiri.

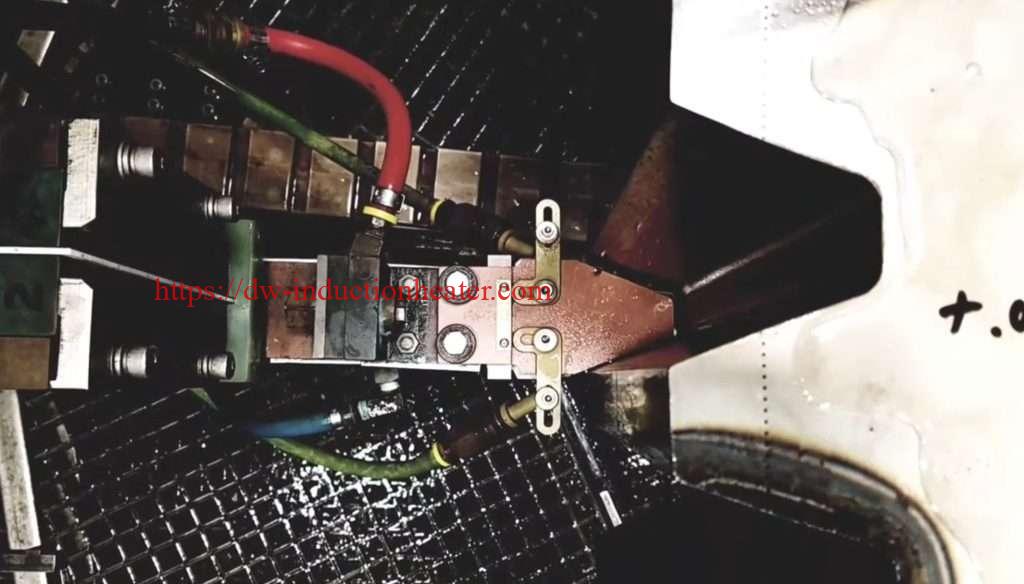

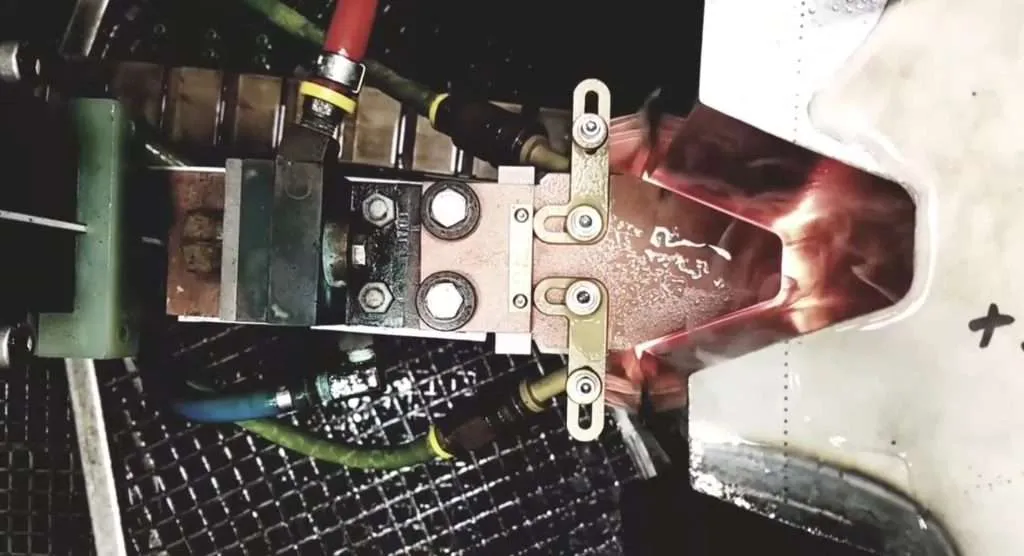

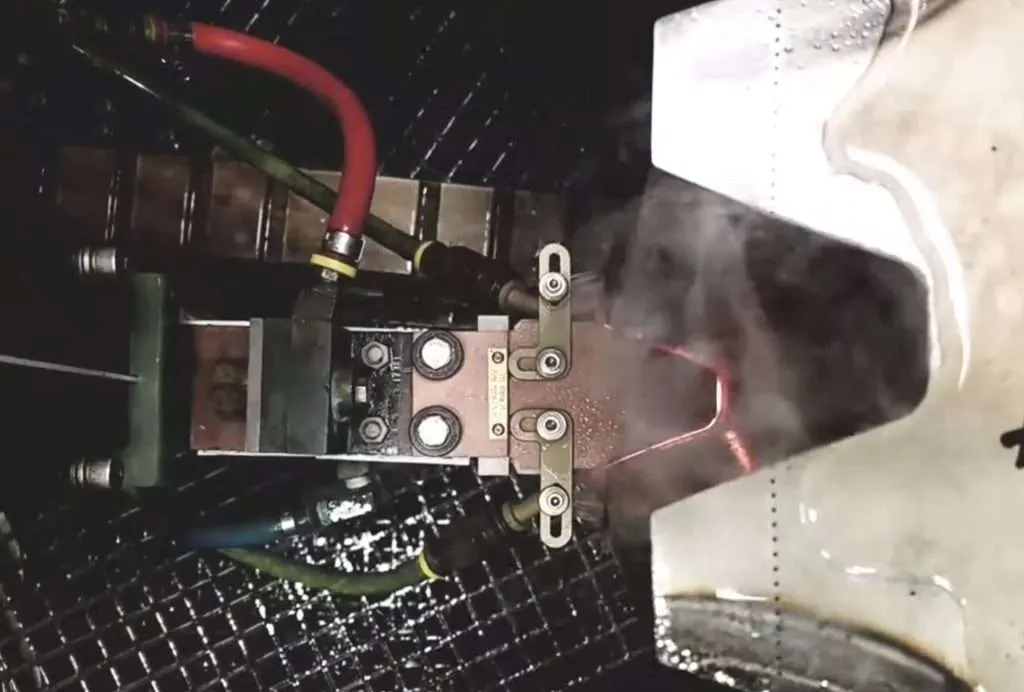

Shahararriyar dabarar taurin "raza-ta-rabi" tana amfani da yanayin dubawa kawai. Yana buƙatar inductor ya kasance daidai gwargwado tsakanin gefuna biyu na haƙoran maƙwabta. Matsakaicin sikanin inductor yawanci tsakanin 6mm/sec zuwa 9mm/sec.

Ana amfani da fasaha na scanning guda biyu:

– Inductor yana tsaye kuma kayan aiki yana iya motsi

- Gear yana tsaye kuma inductor yana iya motsawa (mafi shahara lokacin taurara manyan gears)

Induction hardening Inductor

Inductor Geometry ya dogara da siffar hakora da tsarin taurin da ake buƙata. Za a iya tsara inductors don zafi kawai tushen da/ko gefen hakori, barin tip da ainihin haƙori mai laushi, tauri, da ductile.

Inductor Geometry ya dogara da siffar hakora da tsarin taurin da ake buƙata. Za a iya tsara inductors don zafi kawai tushen da/ko gefen hakori, barin tip da ainihin haƙori mai laushi, tauri, da ductile.

Kwaikwayo yana taimakawa hana zafi fiye da kima

Lokacin haɓaka matakan tauraruwar haƙori-da-haƙori, ya kamata a biya kulawa ta musamman ga tasirin ƙarshen / gefen electromagnetic da ikon samar da tsarin da ake buƙata a wuraren ƙarshen gear.

Bayan duban haƙoran gear, ana rarraba zafin jiki a cikin tushen kayan aiki da gear gaba ɗaya daidai. Har ila yau, tun da eddy halin yanzu yana yin hanyar dawowa ta gefen gefe kuma, musamman ta hanyar haƙori, ya kamata a kula da kyau don hana zafi da zafi a yankunan haƙori, musamman a farkon da kuma a ƙarshen scan hardening. . Simulation zai iya taimakawa wajen hana waɗannan abubuwan da ba'a so kafin haɓaka tsarin.

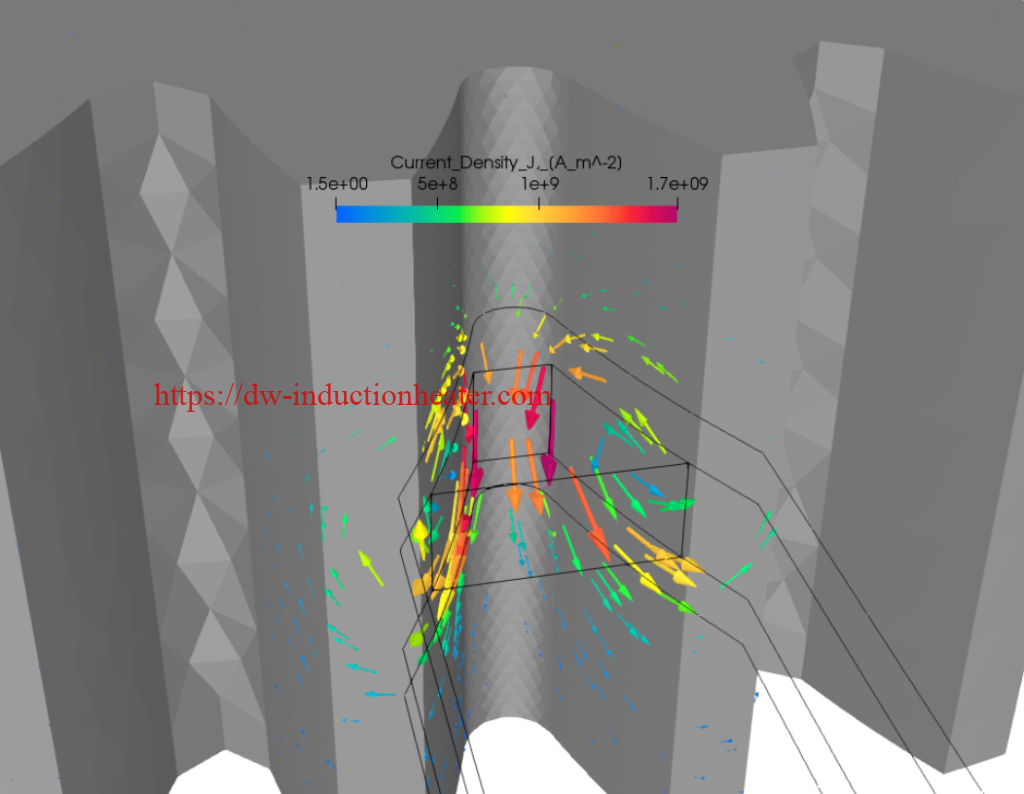

Misalin kwaikwaiyo

Ana duban hakori ta hanyar ƙarar kayan haƙori a 12 kHz.

Hakanan ana siffanta fesa sanyaya amma ba a ganuwa a cikin hotunan sakamakon. Ana amfani da tasirin sanyaya a saman da fuskokin gefen hakora biyu, da kuma motsa yankin sanyaya bin inductor.

3D Hardened profile a cikin launin toka:

2D Hardened profile yanki a tsaye: CENOS yana ba ku damar ganin sauƙin yadda bayanin martabar taurare ke yin zurfi idan ba a rage ƙarfin ko a kashe ba kusa da ƙarshen kayan.

Yawan yawa na yanzu akan kayan aiki:

Bugu da ƙari, ƙaddamar da dumama yana ba da saurin dumama da ƙimar sanyaya, yana rage lokacin sarrafawa gabaɗaya idan aka kwatanta da hanyoyin al'ada. Wannan yana da fa'ida musamman ga manyan gears, saboda yana taimakawa haɓaka haɓakar samarwa da rage farashi.

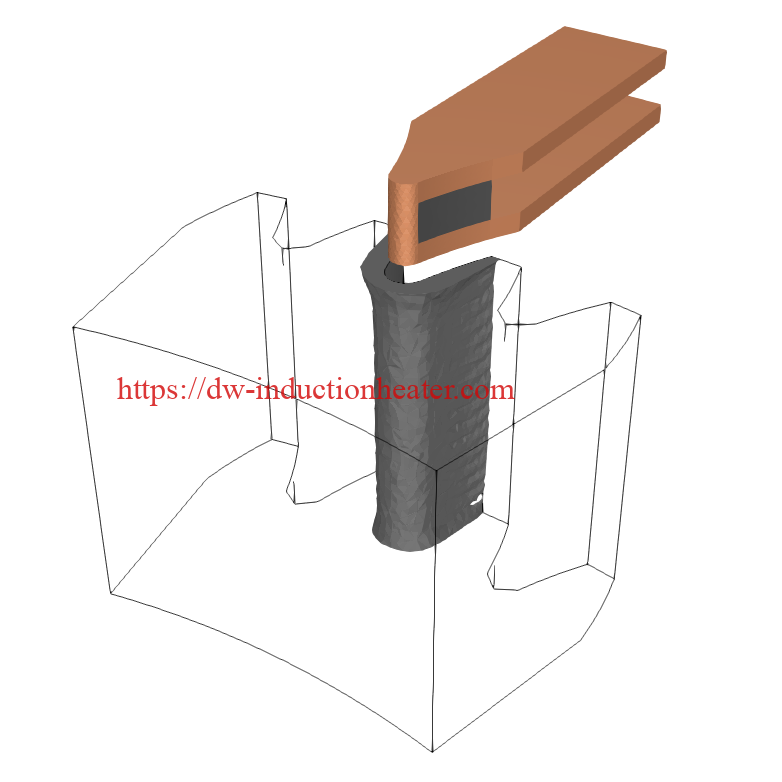

Don cimma taurin haƙori-da-haƙori na manyan gears ta amfani da dumama shigar, ana buƙatar kayan aiki na musamman. Tsarin dumama shigar da yawanci ya ƙunshi wutar lantarki, coil ko inductor, da tsarin sanyaya. An sanya kayan aiki a cikin coil, kuma ana kunna wutar lantarki don samar da zafin da ake bukata. Ma'aunin tsari, kamar wutar lantarki, mita, da lokacin dumama, ana sarrafa su a hankali don cimma bayanin taurin da ake so.

A ƙarshe, taurin haƙori-da-haƙori na manyan kayan aiki ta amfani da dumama shigar da ita hanya ce mai inganci da inganci. Yana tabbatar da rarraba taurin iri ɗaya, taurin zaɓi, da lokutan sarrafawa cikin sauri, yana haifar da inganci, kayan aiki masu ɗorewa. Idan kuna da hannu a cikin kera manyan kayan aiki, la'akari da aiwatar da dumama dumama don taurin haƙori na iya haɓaka aiki da tsayin samfuran ku.