CNC Induction Horizontal Hardening Scanners-Quenching Surface Machines

description

Menene Induction Horizontal Hardening Scanner?

An induction kwance hardening na'urar daukar hotan takardu na'ura ce da ake amfani da ita a masana'antar sarrafa ƙarfe don taurare saman sassan ƙarfe. Yana amfani zaɓin wutar lantarki don dumama karfe, sannan kuma saurin sanyaya, don inganta taurinsa da dorewa.

Na'urar daukar hoto mai taurara a kwance tana wakiltar babban ƙima a fagen injiniyan ƙarfe da hanyoyin magance zafi. Wannan labarin yana ba da zurfafa bincike na ƙirar na'urar daukar hotan takardu a kwance a kwance, ƙa'idodin aiki, mahimman aikace-aikace, da ci gaban da yake kawowa masana'antar. Ta hanyar ba da damar shigar da wutar lantarki, wannan na'ura ta zamani tana ba da damar sarrafa daidaitaccen iko ƙwaƙwalwar shiga na nau'ikan ƙarfe daban-daban, suna haɓaka juriyar lalacewa da haɓaka rayuwar sabis.

Ta yaya Induction Horizontal Hardening Scanner ke aiki?

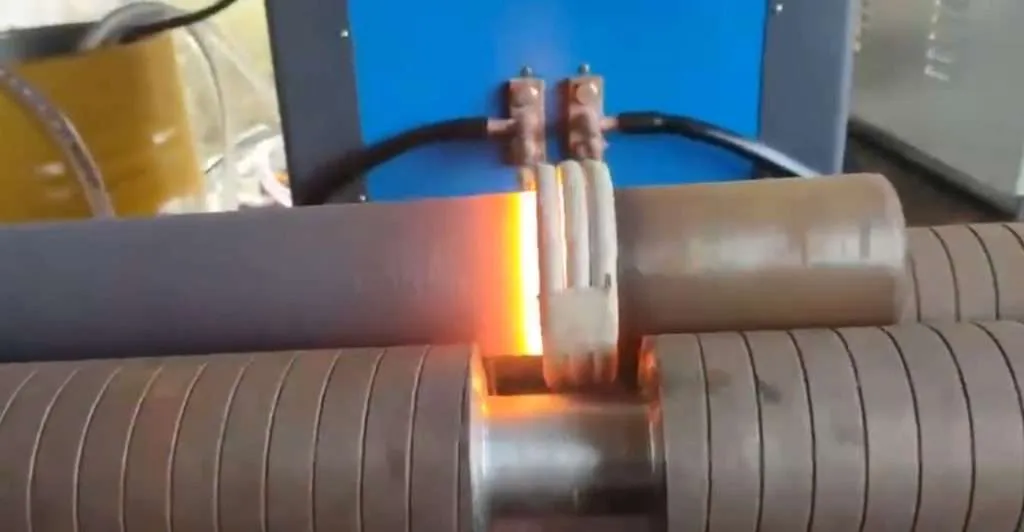

Na'urar daukar hotan takardu tana samar da filin lantarki ta hanyar na'urar induction, tana dumama ɓangaren ƙarfe zuwa takamaiman zafin jiki. Sa'an nan kuma ana sanyaya ɓangaren da sauri, sau da yawa tare da ruwa ko wani matsakaicin kashewa, don taurare saman.

Menene fa'idodin amfani da Induction Horizontal Hardening Scanners?

Menene fa'idodin amfani da Induction Horizontal Hardening Scanners?

Waɗannan na'urorin na'urar daukar hotan takardu suna ba da daidaito a cikin taurare takamaiman yanki na wani yanki, daidaito a cikin sakamakon jiyya, haɓaka haɓakar samarwa saboda saurin sarrafa lokaci, da tanadin kuzari idan aka kwatanta da hanyoyin taurin gargajiya.

- Wadanne masana'antu ne suka fi amfani da Induction Horizontal Hardening Scanners? Masana'antu waɗanda galibi ke amfani da waɗannan na'urori sun haɗa da kera motoci, sararin samaniya, kera kayan aiki, da duk wani yanki da ke buƙatar ingantaccen juriya da dorewar abubuwan ƙarfe.

Can Induction Horizontal Hardening Scanners bi da kowane irin karafa? Duk da yake suna da yawa, tasirin su na iya bambanta dangane da kaddarorin ƙarfe, kamar ƙarfin wutar lantarki da ƙarfin maganadisu. Karfe da aka saba yi da su sun hada da karfe da kayan aikin sa, amma dacewa da sauran karafa ya kamata a yi la'akari da takamaiman bukatu.

Can Induction Horizontal Hardening Scanners bi da kowane irin karafa? Duk da yake suna da yawa, tasirin su na iya bambanta dangane da kaddarorin ƙarfe, kamar ƙarfin wutar lantarki da ƙarfin maganadisu. Karfe da aka saba yi da su sun hada da karfe da kayan aikin sa, amma dacewa da sauran karafa ya kamata a yi la'akari da takamaiman bukatu.

Ƙira da Ƙa'idodin Aiki:

Shigar da ciki a kwance hardening na'urar daukar hotan takardu ya ƙunshi hadaddun haɗaɗɗun coils na inductive, hanyoyin kashewa, da ingantattun tsarin sarrafawa. Yana aiki akan ƙa'idar shigar da wutar lantarki don samar da igiyoyin ruwa da zafi na gida a cikin kayan aikin ƙarfe. Zafin da aka jawo ana sarrafa shi sosai, na sararin samaniya da na ɗan lokaci, don cimma tasirin da ake so. Matsakaicin kashe-yawanci ruwa, mai, ko mafita na polymer - daga baya ana amfani da su don sanyaya wurare masu zafi cikin sauri, kulle cikin taurin. A kwance sanyi na na'urar daukar hotan takardu damar domin masauki elongated workpieces, inganta uniform hardening tsari da kuma ba da damar jiyya na sassa da daban-daban geometries. Ana haɓaka madaidaicin na'urar daukar hotan takardu ta na'urori masu auna firikwensin da software mai sarrafawa, waɗanda ke saka idanu da daidaita sigogi a cikin ainihin lokaci don tabbatar da daidaiton inganci.

Bayanan fasaha na CNC Horizontal Ingancin Hardening Machine Kayan aiki (Za a iya keɓance muku):

Bayanan fasaha na CNC Horizontal Ingancin Hardening Machine Kayan aiki (Za a iya keɓance muku):

|

model

|

LP-SK-600 | LP-SK-1200 | LP-SK-2000 | LP-SK-3000 |

|

Matsakaicin Tsayin Rike (mm)

|

600 | 1200 | 2000 | 3000 |

| Matsakaicin Tsayin Hardening(mm) | 580 | 1180 | 1980 | 2980 |

| Matsakaicin Diamita (mm) | ≤500 | ≤500 | ≤500 | ≤500 |

| Gudun Motsi na Kayan Aiki (mm/s) | 20 ~ 60 | 20 ~ 60 | 20 ~ 60 | 20 ~ 60 |

| Gudun Juyawa (r/min) | 40 ~ 150 | 30 ~ 150 | 25 ~ 125 | 25 ~ 125 |

| Gudun Motsa Hankali (mm/min) | 480 | 480 | 480 | 480 |

| Nauyin Kayan Aiki (kg) | ≤50 | ≤100 | ≤800 | ≤1200 |

| Input Voltage(V) | 3 lokaci na 380V | 3 lokaci na 380V | 3 lokaci na 380V | 3 lokaci na 380V |

| Jimlar Ƙarfin Mota (KW) | 1.1 | 1.2 | 2 | 2.5 |

| Yawan Hardening Kowane Lokaci | Single/Biyu | single | single | single |

The shigar da na'urori masu taurin kai a kwance ya tsaya a matsayin shaida ga ci gaba da neman ƙwararrun fasaha a aikin injiniyan kayan aiki. Ta hanyar samar da ingantacciyar hanya mai inganci, mai inganci, da madaidaici ga taurin ƙarfe, tana taka muhimmiyar rawa wajen haɓaka aiki da dorewar abubuwa masu mahimmanci a cikin masana'antu daban-daban. Yayin da fasahar ke ci gaba da bunkasa, babu shakka za ta kasance a kan gaba wajen samar da sabbin abubuwa, ta tura iyakokin abin da zai yiwu a cikin yanayin yanayin zafi.