Gabatarwa zuwa Ƙarfafa Ƙarfafawa da Zazzaɓi

Menene Induction Hardening?

Ƙarfafa ƙora tsari ne na maganin zafi da ake amfani da shi don zaɓan taurare saman abubuwan ƙarfe na ƙarfe, kamar wayoyi na sanda, yayin da yake riƙe da tushe mai tauri da ductile. Wannan tsari ya haɗa da dumama saman ƙarfen ta amfani da babban juzu'i mai ƙarfi (AC) sannan a hanzarta kashe shi don cimma wani wuri mai wuya, mai jure lalacewa.

Menene Tempering?

Tempering shine tsarin maganin zafi wanda ke biye da taurin. Ya haɗa da sake dumama ƙarfe mai tauri zuwa takamaiman zafin jiki a ƙasa da mahimmin wuri sannan kuma ba shi damar yin sanyi a hankali. Tempering yana inganta tauri, ductility, da juriya na tasiri na karfe ta hanyar kawar da damuwa na ciki da rage raguwa.

Fa'idodin Ƙarfafa Ƙarfafawa da Zazzaɓi

Induction hardening da tempering bayar da fa'idodi da yawa ga wayoyi na sanda na karfe, gami da:

- Ingantacciyar juriya da gajiyarwa

- Ingantacciyar taurin saman yayin da yake riƙe da ductile core

- Madaidaicin iko akan bayanan taurara da taurin

- Saurin aiki da sauri idan aka kwatanta da hanyoyin magance zafi na al'ada

- Amfanin makamashi da dumama gida, rage yawan farashi

Tsarin Kera Waya Karfe

Tsarin Kera Waya Karfe

raw Materials

Wayoyin sandar ƙarfe yawanci ana yin su ne daga ƙananan ma'aunin ƙarfe na carbon ko matsakaici-carbon, kamar AISI 1018, AISI 1045, ko AISI 4140. Ana zaɓar waɗannan maki bisa ga kayan aikin injiniya da ake so da aikace-aikacen amfani na ƙarshe.

Zane Waya

Tsarin zanen waya ya ƙunshi jan sandar ƙarfe mai ƙarfi ta cikin jerin mutuwar tare da ƙarami kaɗan. Wannan tsari yana haɓakawa kuma yana rage ƙetare yanki na sandar, wanda ya haifar da diamita na waya da ake so da kuma ƙarewa.

Jiyya mai zafi

Bayan tsarin zane na waya, wayoyi na sanda na karfe suna yin maganin zafi don cimma abubuwan da ake so. Wannan yawanci ya haɗa da tauraruwar induction da tafiyar matakai na zafin rai.

Tsarin Ƙarfafa Ƙarfe don Wayoyin Ƙarfe na Karfe

Ka'idodin Ƙarfafa Ƙarfafawa

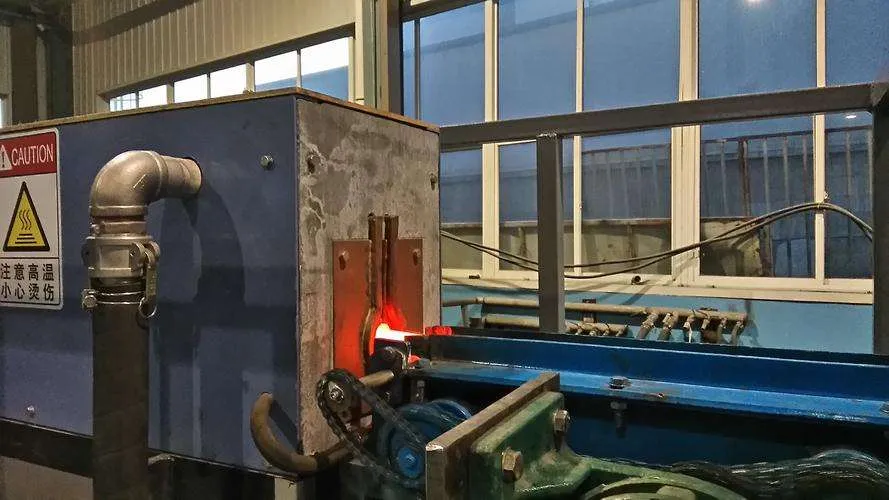

Ƙarƙashin ƙaddamarwa yana amfani da ƙa'idodin shigar da wutar lantarki don samar da zafi a cikin wayar sandar karfe. Madadin halin yanzu yana gudana ta hanyar induction coil, ƙirƙirar filin maganadisu wanda ke haifar da igiyoyin ruwa a cikin wayar karfe. Wadannan igiyoyin ruwa suna haifar da zafi saboda juriya na lantarki na karfe, yana haifar da saman ya isa iyakar zafin jiki na austenitic (yawanci sama da 1600 ° F ko 870 ° C).

Induction Hardening Kayan aiki

Induction Hardening Kayan aiki

Induction Hardening Coils

Induction coils sune zuciyar tsarin tauraruwar shigar. An ƙera su don mayar da hankali kan filin maganadisu a kusa da wayar sandar karfe, tabbatar da ingantaccen kuma dumama gida. Zane-zanen nada, gami da siffarsa, girmansa, da adadin juyi, an inganta shi don takamaiman aikace-aikacen.

Uarfafa Suppliesarfin wutar lantarki

Kayayyakin wutar lantarki suna ba da babban madaidaicin halin yanzu da ake buƙata don dumama shigar. Suna iya aiki a mitoci daga ƴan kilohertz zuwa megahertz da yawa, dangane da zurfin dumama da ake buƙata da saurin samarwa.

Quenching Systems

Ana amfani da tsarin quenching don saurin kwantar da zafin saman igiyar sandar karfe bayan dumama shigar. Kafofin watsa labaru na gama-gari sun haɗa da ruwa, mafita na polymer, ko iska mai tilastawa. Matsakaicin kashewa yana da mahimmanci don cimma taurin da ake so.

Induction Hardening Parameters

Induction Hardening Parameters

Frequency

Matsakaicin madaidaicin halin yanzu yana ƙayyade zurfin dumama da ƙimar dumama. Maɗaukakin mitoci suna haifar da zurfin dumama mai zurfi, yayin da ƙananan mitoci ke shiga zurfi cikin kayan.

2. H4: Ƙarfi

Shigar da wutar lantarki yana sarrafa ƙimar dumama da zafin da aka samu yayin aiwatar da taurin shigar. Madaidaicin ikon sarrafa wutar yana da mahimmanci don tabbatar da dumama iri ɗaya da guje wa zafi mai zafi ko ƙasa da ƙasa.

Time

Tsawon lokacin zagayowar dumama shigarwa yana ƙayyadaddun zurfin shari'ar taurare da gabaɗayan shigar zafi. Ana amfani da gajeriyar lokutan dumama don sassa na bakin ciki, yayin da ake buƙatar lokaci mai tsawo don sassa masu kauri.

Tsarin zafin jiki don Wayoyin Karfe

Muhimmancin Tsanani

Bayan shigar da hardening, karfe sandar wayoyi suna cikin wani gaggautsa yanayi saboda samuwar martensite, mai wuya amma gaggautsa microstructure. Tempering yana da mahimmanci don rage ɓarna da haɓaka ƙarfin ƙarfi da ductility na karfe yayin da yake riƙe isasshen ƙarfi.

Hanyoyin zafi

Tanda mai zafi

Tanda ya haɗa da dumama igiyoyin sandar ƙarfe masu tauri a cikin tanderun yanayi mai sarrafawa a takamaiman zafin jiki, yawanci tsakanin 300°F da 1200°F (150°C da 650°C), na ƙayyadadden lokaci. Wannan tsari yana ba da damar martensite don canzawa zuwa mafi kwanciyar hankali da ƙananan microstructure.

Induction Tempering

Induction tempering hanya ce ta baya-bayan nan kuma ingantacciya don zafin wayoyi na sanda na karfe. Yana amfani da ƙa'idodi iri ɗaya kamar hardening induction, amma a ƙananan yanayin zafi da tsayin lokacin dumama. Wannan tsari yana ba da damar madaidaicin iko akan zafin zafin jiki kuma ana iya haɗa shi tare da tsarin hardening na shigarwa don ingantacciyar aiki.

Tempering Siga

Zafin jiki

Matsakaicin zafin jiki yana da mahimmanci wajen tantance kaddarorin injina na ƙarshe na wayar sandar ƙarfe. Maɗaukakin zafin jiki gabaɗaya yana haifar da ƙananan taurin amma ingantaccen ductility da juriya mai tasiri.

Time

Lokacin zafin jiki yana tabbatar da cewa canjin da ake so microstructural yana faruwa daidai gwargwado a ko'ina cikin akwati mai tauri. Ana iya buƙatar lokutan zafi mai tsayi don sassa masu kauri ko lokacin da ake neman takamaiman kayan inji.

Gwajin Inganci da Gwaji

A. Gwajin Tauri

Gwajin taurin shine ainihin ma'aunin sarrafa inganci don tauraruwar shigar da wayoyi na sanda na karfe. Hanyoyin gwajin taurin gama gari sun haɗa da gwajin Rockwell, Vickers, da gwajin Brinell. Waɗannan gwaje-gwajen suna tantance bayanan taurin kai a cikin ɓangaren giciye na waya, suna tabbatar da cewa an cimma ƙimar taurin da ake so.

B. Ƙididdigar Ƙira

Binciken microstructure ya ƙunshi nazarin tsarin ƙarfe na sandar ƙarfe ta hanyar amfani da dabaru irin su microscopy na gani ko sikanin microscopy na lantarki (SEM). Wannan bincike yana tabbatar da kasancewar matakan ƙananan matakan da ake so, irin su martensite mai zafi, kuma yana gano duk wani lahani ko rashin daidaituwa.

C. Gwajin Injini

Gwajin injina, gami da juzu'i, gajiya, da gwaje-gwajen tasiri, ana yin su don kimanta gabaɗayan kaddarorin inji na induction taurare da zafin wayoyi na sanda na ƙarfe. Waɗannan gwaje-gwajen suna tabbatar da cewa wayoyi sun cika ƙayyadaddun ƙarfi, ductility, da buƙatun tauri don aikace-aikacen da aka yi niyya.

Aikace-aikace na Induction Hardened da Ƙarfe Mai Ƙarfe Waya

A. Masana'antar Motoci

A. Masana'antar Motoci

Induction taurare da zafin wayoyi na ƙarfe na ƙarfe ana amfani da su sosai a cikin masana'antar kera motoci don sassa daban-daban, kamar maɓuɓɓugan dakatarwa, maɓuɓɓugan bawul, da abubuwan watsawa. Waɗannan wayoyi suna ba da ƙarfi mai ƙarfi, juriya, da rayuwar gajiya, waɗanda ke da mahimmanci don amintaccen aiki mai dorewa.

B. Masana'antar Gine-gine

A cikin masana'antar gine-gine, ana amfani da wayoyi masu taurin ƙarfe na ƙarfe mai ƙarfi don ƙarfafawa a cikin simintin simintin, aikace-aikacen simintin da aka riga aka yi, da igiyoyin waya don cranes da lif. Ƙarfin ƙarfi da ƙarfin waɗannan wayoyi suna tabbatar da aminci da tsawon rayuwar ayyukan gine-gine.

C. Masana'antar Masana'antu

Masana'antar masana'anta tana amfani da wayoyi masu ƙarfi na ƙarfe mai ƙarfi da zafin wuta a aikace-aikace daban-daban, kamar kayan aikin injin, bel na jigilar kaya, da maɗaurin masana'antu. Waɗannan wayoyi suna ba da ƙarfin da ake buƙata, juriya, da kwanciyar hankali da ake buƙata a cikin buƙatar yanayin masana'anta.

Kammalawa

Kammalawa

A. Takaitawa

Ƙunƙarar ƙaddamarwa da zafin jiki sune mahimman hanyoyin magance zafi don wayoyi na sanda na ƙarfe, suna ba da haɗe-haɗe na musamman na taurin saman, juriya, da taurin gaske. Ta hanyar sarrafa tauraruwar shigar da a hankali da ma'aunin zafin jiki, masana'antun na iya keɓance kaddarorin inji na wayoyi na sandar ƙarfe don biyan takamaiman buƙatun masana'antu daban-daban, gami da kera, gini, da masana'antu.

B. Abubuwan Gaba da Ci gaba

Yayin da fasaha ke ci gaba da haɓakawa, ana sa ran tauraruwar ƙaddamarwa da matakan zafi za su zama mafi inganci, daidaici, da abokantaka na muhalli. Ci gaba a fasahar samar da wutar lantarki, ƙirar coil, da sarrafa kayan aiki za su ƙara haɓaka inganci da daidaiton induction taurare da wayoyi na ƙarfe na ƙarfe. Bugu da ƙari, ci gaba da bincike a kimiyyar ƙarfe da kayan aiki na iya haifar da haɓaka sabbin kayan haɗin gwiwa na ƙarfe da sabbin dabarun magance zafi, faɗaɗa aikace-aikace da iya aiki na waɗannan wayoyi.

FAQs

FAQs

1. Menene bambanci tsakanin hardening induction da tsarin taurara na al'ada? Ƙunƙarar ƙaddamarwa tsari ne mafi ƙanƙanta kuma ingantaccen aiki idan aka kwatanta da hanyoyin taurara na al'ada, kamar taurin tanderu ko taurin harshen wuta. Yana ba da damar ƙwaƙƙwaran takamaiman wurare yayin da ke riƙe maɓallin ductile, kuma yana ba da lokutan aiki da sauri da ingantaccen ƙarfin kuzari.

2. Za a iya amfani da hardening induction zuwa wasu kayan bayan karfe? Duk da yake ana amfani da tauraruwar induction da farko don kayan haɗin ƙarfe, ana kuma iya amfani da shi ga wasu kayan aikin ferromagnetic, kamar simintin ƙarfe da wasu abubuwan gami na tushen nickel. Koyaya, sigogin tsari da buƙatun na iya bambanta dangane da abun da ke ciki da kaddarorin kayan.

3. Yaya zurfin za'a iya samun harka mai tauri ta hanyar hardening induction? Zurfin shari'ar taurare a cikin tauraruwar shigar ya dogara da abubuwa da yawa, gami da mitar canjin halin yanzu, shigar da wutar lantarki, da lokacin dumama. Yawanci, zurfin harka mai tauri yana daga 0.5 mm zuwa 6 mm, amma ana iya samun mafi zurfi ta hanyar fasaha na musamman ko hawan dumama.

4. Shin fushi yana da mahimmanci a koyaushe bayan hardening induction? Ee, zafin jiki yana da mahimmanci bayan ƙaddamar da ƙaddamarwa don rage ɓarnawar ƙarfe mai tauri da haɓaka taurinsa da ductility. Ba tare da fushi ba, ƙarfe mai taurin zai kasance mai karyewa sosai kuma yana da saurin fashewa ko guntuwa ƙarƙashin kaya ko tasiri.

5. Za a iya yin hardening induction da zafin rai azaman tsari guda ɗaya? Ee, na zamani shigar da hardening tsarin sau da yawa haɗa tsarin zafin jiki tare da tsarin hardening, yana ba da damar ci gaba da ingantaccen tsarin kula da zafi. Wannan haɗin kai yana taimakawa wajen inganta lokutan samarwa da kuma tabbatar da daidaiton inganci a cikin dukan tsari.