Fushin Sintering Furnace-Maɗaukakin Zazzabi Wutar Wuta

description

Vacuum Sintering Furnace / Wuraren Wutar Wuta Mai Ruwa wani yanki ne na musamman da ake amfani da shi wajen kerawa da sarrafa kayayyaki, musamman a fannin karafa da tukwane. An ƙera wannan nau'in tanderun don ƙirƙirar yanayi tare da yanayin yanayi mai sarrafawa, yawanci ya haɗa da ƙarancin matsa lamba da takamaiman abubuwan haɗin iskar gas, don cimma daidaitattun sakamako masu ɓarna.

Application:

Yanayin da ba shi da carbon, gyaran gyare-gyaren ƙarfe na ƙarfe (MIM), ƙarfe, sintering, Superhard gami, samfuran graphite, da sauransu.

Kayan fasali

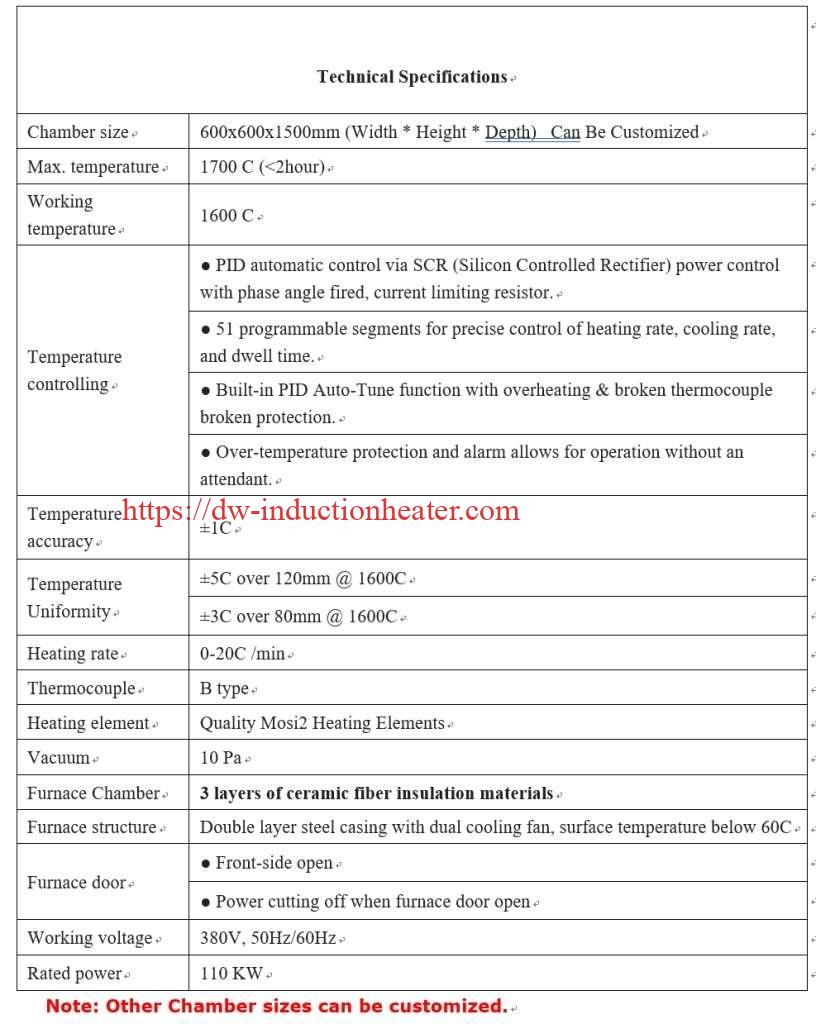

- Tanderun wuta suna ba da yanayin ƙayyadaddun yanayi tare da mafi girman tsafta

- Matsakaicin digiri na Vacuum zuwa -0.01Pa

- Matsakaicin amfani da zafin jiki har zuwa 1700c

- Duban ciki na kyamarar zafin jiki ya zama mai yiwuwa

- Tanderu suna ba da mafi kyawun injin da zai yiwu

- Aikin wani bangare na matsa lamba hydrogen idan an buƙata

- Madaidaicin sarrafa injin famfo gudun da ya dace da foda

- Rikodin bayanai don gudanarwa mai inganci

- Kariyar matsin lamba

- Ƙananan tasirin yanayi

- Tsarin sanyaya: iska + Ruwan sanyaya

- Kariyar madaukai biyu. (Sama da kariyar zafin jiki, Kariyar wutar lantarki da sauransu)

- Ikon allon taɓawa

Misali Tanderu Na Musamman:

Sintering wani tsari ne na ƙaddamarwa da kuma samar da wani abu mai ƙarfi ta hanyar zafi da / ko matsa lamba ba tare da narkar da shi ba har zuwa ma'anar liquefaction. Ana amfani da wannan tsari sosai wajen samar da sassa na ƙarfe na foda, yumbu, da sauran kayan inda ake buƙatar ƙarfi da daidaito. Wuraren murɗawar yanayi suna taka muhimmiyar rawa wajen cimma abubuwan da ake so da ingancin samfur na ƙarshe.

Sintering wani tsari ne na ƙaddamarwa da kuma samar da wani abu mai ƙarfi ta hanyar zafi da / ko matsa lamba ba tare da narkar da shi ba har zuwa ma'anar liquefaction. Ana amfani da wannan tsari sosai wajen samar da sassa na ƙarfe na foda, yumbu, da sauran kayan inda ake buƙatar ƙarfi da daidaito. Wuraren murɗawar yanayi suna taka muhimmiyar rawa wajen cimma abubuwan da ake so da ingancin samfur na ƙarshe.

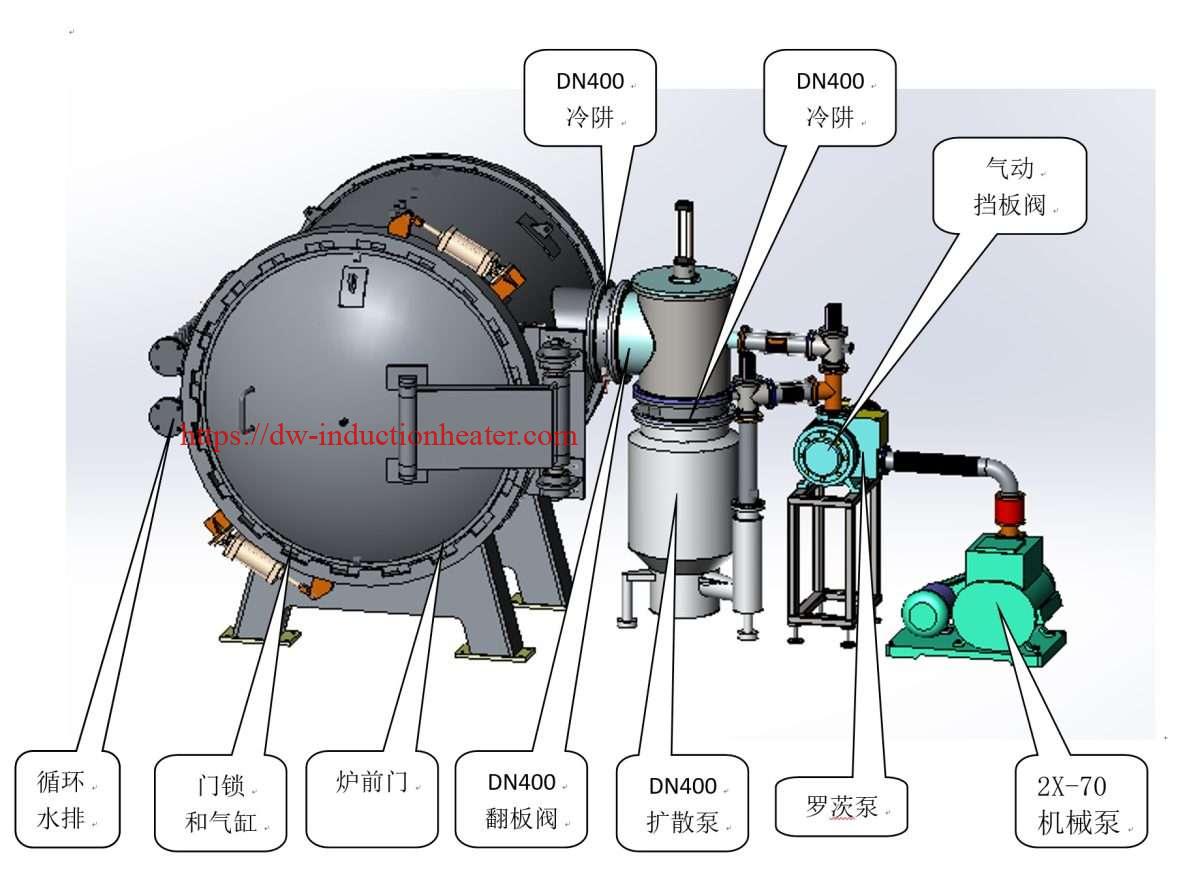

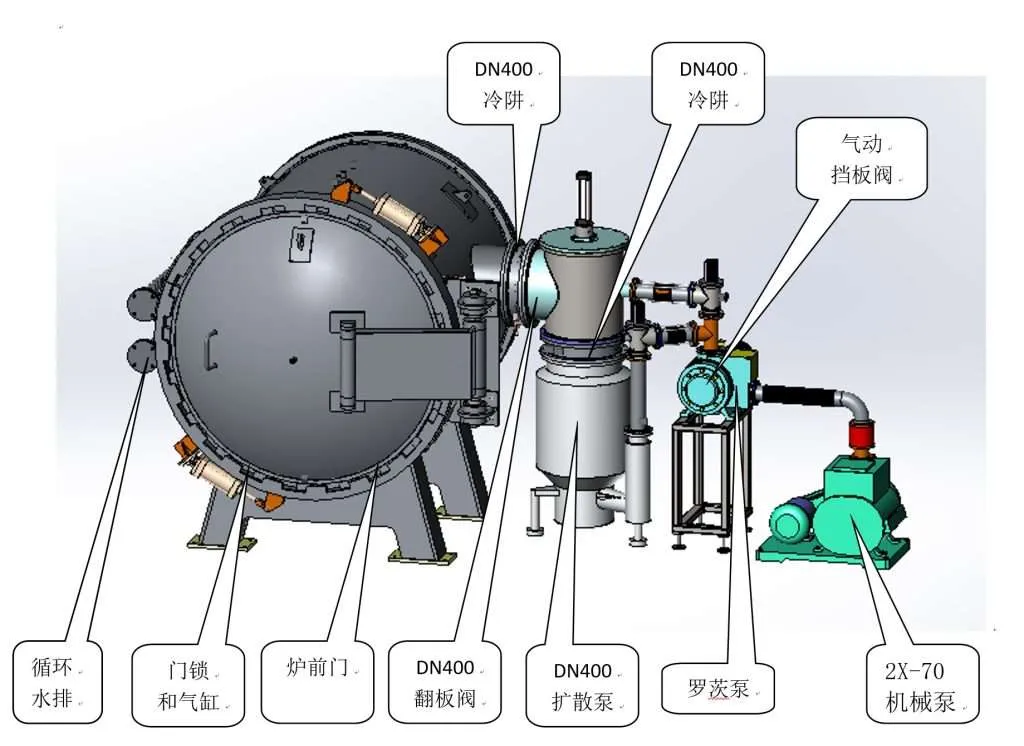

Mabuɗin abubuwan a injin yanayi sintering makera sun haɗa da ɗakin ɗaki, abubuwan dumama, tsarin samar da iskar gas, tsarin kula da zafin jiki, da kayan kariya. Wurin vacuum wani shinge ne da aka rufe inda aikin sintiri ke faruwa a ƙarƙashin ƙananan yanayi. Wannan yana taimakawa wajen hana oxidation da gurɓataccen kayan da ake sarrafa, wanda ke da mahimmanci don samun samfuran sintered masu inganci.

Abubuwan dumama suna da alhakin samar da wutar lantarki mai mahimmanci don ɗaga zafin jiki a cikin tanderun zuwa matakan da ake buƙata don sintiri. An tsara waɗannan abubuwan a hankali don tabbatar da dumama iri ɗaya a cikin ɗakin ɗaki, wanda ke da mahimmanci don samun daidaiton sakamako a cikin dukkan nau'ikan kayan da ake sarrafa su.

Ana amfani da tsarin samar da iskar gas don shigar da takamaiman iskar gas a cikin ɗakin da ake so don haifar da yanayin da ake so don tsarin simintin. Gas na yau da kullun da ake amfani da su a cikin ɓoyayyen yanayi sun haɗa da hydrogen, nitrogen, argon, da samar da iskar gas (cakuɗin hydrogen da nitrogen). Madaidaicin sarrafa abun da ke tattare da iskar gas da matsa lamba yana da mahimmanci don cimma abubuwan da ake so da kuma hana halayen da ba'a so yayin aikin sintiri.

Tsarin kula da yanayin zafi yana da mahimmanci don kiyaye madaidaicin bayanan zafin jiki a duk lokacin da ake yin kitse. Waɗannan tsarin yawanci sun haɗa da ma'aunin zafi da sanyio, masu kula da zafin jiki, da na'ura mai sarrafa wutar lantarki don tabbatar da cewa kayan da ake sarrafa sun kasance ƙarƙashin madaidaicin yanayin zafi da ake buƙata don cin nasara.

Ana amfani da kayan haɓakawa don rage asarar zafi daga ɗakin ɗaki da kuma samar da kariya ta zafi don yanayin kewaye. Wannan yana taimakawa inganta haɓakar makamashi da kiyaye yanayin aiki mai ƙarfi a cikin tanderun.

Aiki na vacuum yanayi sintering makera ya ƙunshi matakai masu mahimmanci da yawa. Da farko, ana ɗora kayan da za a ɗora a cikin ɗakin tanderun, wanda aka rufe kuma an kwashe shi don haifar da ƙananan yanayi. Da zarar an sami matakin injin da ake so, ana kunna abubuwan dumama don ɗaga zazzabi a cikin ɗakin zuwa yanayin da ake buƙata. A lokaci guda kuma, ana shigar da iskar gas na musamman a cikin ɗakin don ƙirƙirar yanayin da ake so don tsarin sintiri. Yanayin zafin jiki da abun da ke ciki na gas ana sarrafa su a hankali a duk lokacin da ake zagayawa don tabbatar da cewa kayan sun sami canjin yanayin zafi da canjin sinadarai don cimma abubuwan da ake so.

Amfanin amfani da a injin yanayi sintering makera sun haɗa da daidaitaccen iko akan tsarin sintiri, yana haifar da samfuran inganci masu inganci tare da kaddarorin iri. Ikon ƙirƙirar ƙayyadaddun yanayin yanayi yana ba da damar sarrafa kayan da aka keɓance, kamar rage iskar oxygen, sarrafa haɓakar hatsi, da haɓaka takamaiman canje-canjen lokaci. Bugu da ƙari, yin amfani da mahalli na iya rage ƙazanta da inganta ɗaukacin tsaftar kayan da aka ƙera.

A taƙaice, vacuum sintering furnace-injin yanayi sintering makera wani nagartaccen kayan aiki ne wanda ke taka muhimmiyar rawa wajen samar da ingantattun kayan sinadarai. Ta hanyar samar da yanayin yanayi mai sarrafawa, daidaitaccen yanayin zafin jiki, da dumama iri ɗaya, waɗannan tanderun suna ba wa masana'antun damar cimma daidaito da ingantaccen sakamako a cikin samar da sassan ƙarfe na foda, yumbu, da sauran kayan haɓaka.

Wutar Wuta ta Wuta En