Induction dumama coils nau'in nau'in dumama ne da aka saba amfani da shi a tsarin dumama shigar da shi. Wadannan coils yawanci ana yin su ne da tagulla ko wasu kayan aiki kuma an ƙera su ne don samar da musanyawan filin maganadisu lokacin da canjin wutar lantarki ya ratsa su. Madaidaicin filin maganadisu yana haifar da igiyoyin ruwa a cikin abin da ake dumama, yana haifar da zafi da sauri. Induction dumama coils ana amfani da ko'ina a cikin daban-daban aikace-aikace na masana'antu kamar karfe aiki, zafi magani, da kuma sayar da, kamar yadda suke bayar da sauri da kuma ingantaccen dumama tare da daidai zafin jiki kula.

A cikin duniyar yau mai saurin tafiya, masana'antu koyaushe suna neman sabbin hanyoyin inganta masana'antu. Ɗayan irin wannan ci gaban fasaha wanda ya canza fasahar maganin zafi shine induction dumama na'ura. Induction dumama coils ana amfani da ko'ina a cikin daban-daban masana'antu, ciki har da mota, aerospace, lantarki, da kuma masana'antu, saboda su iya samar da zafi da sauri da kuma daidai. Wannan labarin yana nufin bincika ƙa'idodin aiki, aikace-aikace, fa'idodi, da kuma abubuwan da za a sa gaba na induction dumama coils.

1. Ƙa'idodin Aiki na Ƙaƙwalwar Ƙwararrun Ƙwararru

Induction dumama coils suna aiki akan ka'idar shigar da wutar lantarki. Tsarin ya haɗa da wucewa ta hanyar wutar lantarki (AC) ta hanyar nada, wanda ke haifar da filin maganadisu. Lokacin da aka sanya kayan aiki a cikin wannan filin maganadisu, ana haifar da igiyoyin ruwa a cikin kayan. Wadannan raƙuman ruwa suna haifar da zafi saboda juriya na kayan. Za'a iya sarrafa zafi da aka haifar ta hanyar daidaita mita da ƙarfin madaidaicin halin yanzu.

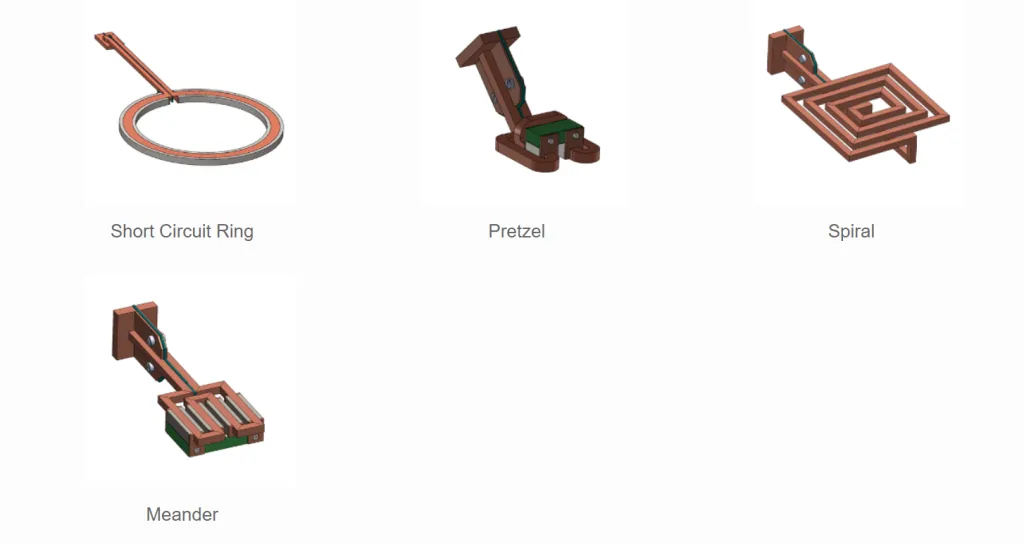

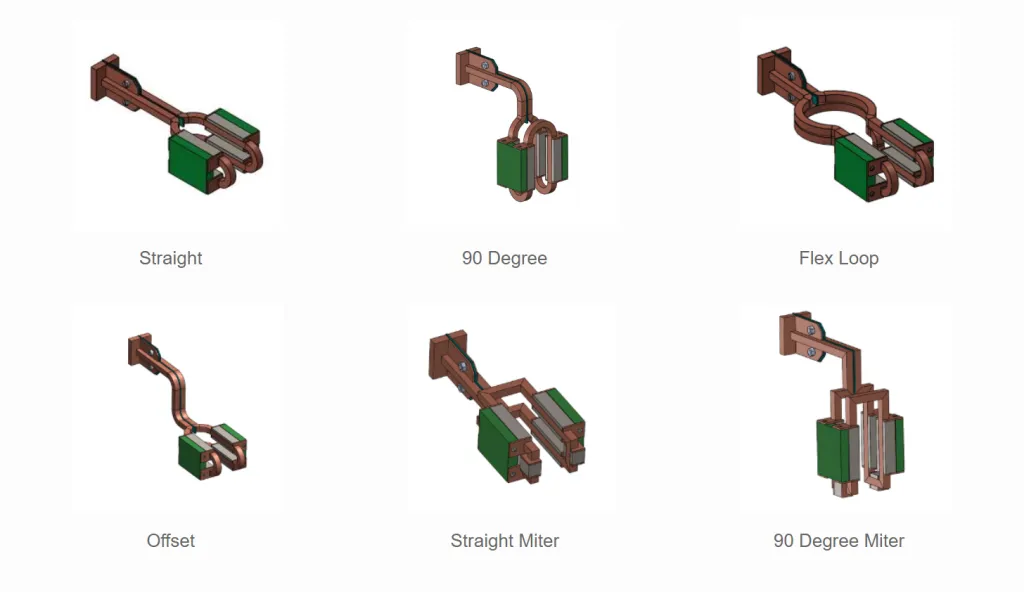

2. Nau'in Induction Dumama Na'ura

Akwai nau'ikan induction dumama da yawa akwai, kowanne an tsara shi don takamaiman aikace-aikace. Wasu nau'ikan gama gari sun haɗa da:

2.1. Helical Heating Coils

Helical coils sun ƙunshi raunin waya ɗaya a cikin siffar helix. Sun dace da dumama abubuwa masu cylindrical, irin su bututu ko sanduna, kamar yadda siffar helical ta ba da damar dumama iri ɗaya tare da tsawon abu.

2.2. Pancake Coils

Pancake coils, kuma aka sani da lebur coils, lebur ne, madauwari coils waɗanda suka dace don dumama lebur ko abubuwa marasa siffa. Suna samar da filin maganadisu mai daɗaɗɗa, yana tabbatar da ingantaccen da dumama wuri.

2.3. Cylindrical Coils

An tsara coils na Silindrical don dumama manyan abubuwa masu siliki, kamar ganga ko tankuna. Yawanci an yi su ne da jujjuyawar wayoyi da yawa a kusa da silinda, suna ba da filin maganadisu iri ɗaya don ko da dumama.

2.4. Induction Coils don Hardening

Induction coils for hardening su ne na musamman coils da aka yi amfani da su a cikin tsarin kula da zafi da aka sani da ƙaddamar da hardening. An ƙera waɗannan muryoyin don cimma saurin ɗumama daidaitattun wurare na ɓangaren ƙarfe, wanda ke haifar da ƙara tauri da juriya.

2.5 Ƙwallon ƙafa

Cokali mai yatsa yana da cokali mai yatsa guda biyu tin waɗanda ake amfani da su don zafi biyu masu adawa da wani workpiece. Ana amfani da su sau da yawa don aikace-aikacen brazing.

3. Aikace-aikace na Induction Heating Coils

3. Aikace-aikace na Induction Heating Coils

3.1. Tauraruwar saman

Ɗaya daga cikin aikace-aikacen farko na induction dumama coils shine taurin saman. Dumamar da aka keɓance ta waɗannan coils suna ba da izini daidaitaccen iko akan tsarin taurin, yana haifar da ingantacciyar juriya da juriya na abubuwa kamar gears, shafts, da bearings.

3.2. Brazing da Soldering

Induction dumama coils ana amfani da ko'ina a brazing da soldering aikace-aikace. Gaggawa da dumama wuri da waɗannan coils ke bayarwa yana ba da damar haɗawa da kayan haɗin ƙarfe daban-daban, gami da bututu, wayoyi, da kayan lantarki.

3.3. Annealing da Rage damuwa

Hakanan ana amfani da coils ɗin dumama shigar da ƙara don kawar da damuwa da tafiyar matakai. Waɗannan matakan sun haɗa da dumama abubuwan ƙarfe zuwa takamaiman zafin jiki sannan a hankali sanyaya su. Induction dumama coils suna samar da madaidaicin dumama mai sarrafawa, yana tabbatar da daidaito a cikin ɓangaren.

3.4. Rage Daidaitawa

Shrink fitting wani tsari ne wanda ya haɗa da dumama kayan ƙarfe don faɗaɗa shi, yana ba da damar haɗuwa da sauƙi tare da wani sashi. Induction dumama coils suna samar da dumama cikin sauri da wuri, yana mai da su manufa don rage aikace-aikacen dacewa a cikin masana'antu kamar kera motoci da masana'antu.

3.5. Narkewa da Yin Wasa

Induction dumama coils yawanci amfani dashi don narkewa da simintin ƙarfe. Dumama mai girma da waɗannan coils ke bayarwa yana ba da damar narkar da ƙarfi da sarrafa karafa daban-daban, gami da ƙarfe, aluminum, da tagulla.

4. Amfanin Induction Dumama Coils

4.1. Inganci da Taimakon Makamashi

Induction dumama coils suna ba da ingantaccen ƙarfin kuzari saboda ikon su na samar da zafi kai tsaye a cikin kayan da ake dumama. Wannan yana kawar da buƙatar preheating kuma yana rage yawan asarar zafi, yana haifar da tanadin makamashi mai mahimmanci.

4.2. Saurin Zafafawa

Induction dumama coils suna ba da saurin dumama, yana ba da izini ga gajeriyar lokutan tsari da ƙara yawan aiki. Wannan yana da fa'ida musamman a masana'antu inda lokaci ke da mahimmanci, kamar kera motoci da na'urorin lantarki.

4.3. Daidaitaccen Dumi da Sarrafa

Induction dumama coils suna ba da madaidaicin dumama mai sarrafawa, yana bawa masana'antun damar cimma daidaito da sakamako iri ɗaya. Ƙarfin daidaitawa da iko da mita na madaidaicin halin yanzu yana ba da damar sarrafa madaidaicin zafin jiki, tabbatar da sakamakon maganin zafi da ake so.

4.4. Amintacciya da Abokan Muhalli

Induction dumama coils amintattu ne kuma maganin dumamar yanayi. Yayin da zafi ke haifar da kai tsaye a cikin kayan da ake dumama, babu buɗaɗɗen harshen wuta ko wuri mai zafi, yana rage haɗarin haɗari. Bugu da ƙari, induction dumama ba sa haifar da hayaki mai cutarwa ko sharar gida, yana mai da su zaɓi mai dorewa.

5. Gabatarwa da Sabuntawa

Filin induction dumama coils yana ci gaba da haɓakawa, tare da ci gaba da bincike da ci gaba da aka mayar da hankali kan haɓaka ayyukansu da faɗaɗa aikace-aikacen su. Wasu tsammanin nan gaba da sabbin abubuwa sun haɗa da:

5.1. Haɗin kai tare da Fasahar Masana'antu 4.0

Haɗuwa da induction dumama coils tare da fasahar masana'antu 4.0, kamar hankali na wucin gadi da Intanet na Abubuwa (IoT), yana da babban yuwuwar. Wannan haɗin kai zai iya ba da damar saka idanu na ainihi da kuma sarrafa tsarin dumama, inganta ingantaccen aiki da yawan aiki.

5.2. Ci gaba a cikin Tsarin Coil

Ci gaba a cikin ƙira na coil, kamar amfani da kayan ci-gaba da na'urorin geometries, na iya ƙara haɓaka inganci da aikin induction dumama coils. Waɗannan ci gaban na iya haifar da ingantacciyar rarraba zafi, rage yawan amfani da makamashi, da ƙara ƙarfin ƙarfi.

5.3. Haɓaka Sabbin Hanyoyi masu dumama

Masu bincike suna ci gaba da binciken sabbin dabarun dumama ta amfani da induction dumama coils. Dabaru kamar dumama zaɓaɓɓu, inda takamaiman wuraren da ke da zafi, da dumama abubuwa da yawa a lokaci guda ana nazarin abubuwan da za su iya amfani da su a masana'antu daban-daban.

Kammalawa

Induction dumama coils sun canza fasahar maganin zafi, suna ba da ingantacciyar mafita, daidaici, da sarrafa hanyoyin dumama. Aikace-aikacen su a cikin taurarewar ƙasa, brazing, annealing, da sauran matakai da yawa sun inganta tsarin masana'antu sosai a cikin masana'antu daban-daban. Tare da ci gaba da ci gaba da sabbin abubuwa, makomar induction dumama coils yana da kyau, tare da yuwuwar haɗin kai tare da fasahar masana'antu 4.0 da haɓaka sabbin dabarun dumama. Kamar yadda masana'antu ke ci gaba da ƙoƙari don haɓaka aiki da dorewa, induction dumama na'urorin babu shakka za su taka muhimmiyar rawa wajen cimma waɗannan manufofin.