Tanadin makamashi a shigar da hatsi tare da hanyar dumama wuta

A kowace shekara Kazakhstan tana samar da kusan tan miliyan 17-19 na hatsi a tsafta, ana fitar da hatsi kimanin tan miliyan 5, kuma matsakaicin yawan amfanin gida ya kai tan miliyan 9-11. Furtherarin ci gaban masana'antar hatsi da haɓaka fitar da hatsi yana buƙatar haɓaka ababen ajiya, jigilar kayayyaki da bushewar hatsi, gami da gina sabon da sake ginin tsohuwar silos ɗin hatsi, gina tashoshin jiragen ruwa da siyan busassun jiragen ruwa da masu jigilar hatsi. (Baum, 1983). Akwai bukatar zamanantar da masana'antar kuma aikin yana bukatar himma mai karfi daga jihar da masu noman hatsi na kasa.

Mahalarta Taron Hatsi na Astana Kazakh V KAZGRAIN-2012 sun tattauna halin kasuwar hatsi a halin yanzu, yanayin tafiya da tsammanin farashi, gami da matsalolin ƙalubale a cikin kayan aiki da kayayyakin more rayuwa. An lura cewa shekaru 10 da suka gabata ba za a iya ɗaukar Kazakhstan a matsayin mai fitar da hatsi ba, yayin da a halin yanzu ana fahimtar batutuwan fitarwa a matsayin waɗanda ke da fifiko. Kuma samarwa da bushewar hatsi na ɗaukar ɗayan manyan wurare duka a cikin hadaddiyar gonar noma, da tattalin arziki gabaɗaya.

Nazarin kwarewar masana'antun masana'antu da yawa a cikin sarrafa hatsi bayan girbi ya tabbatar da cewa babban aikin tabbatar da aminci da ingancin sabbin tsaba da suka girbe shine bushewar su. Mahimmancin bushewar hatsi yana ƙaruwa a yankin mai danshi: jinkiri a bushewa ko aiwatar da wannan aiki tare da keta gwamnatocin fasaha babu makawa yana haifar da asarar amfanin gona. Dangane da binciken da aka yi a cikin kashi 25-28% na dusar ruwa tsawon kwana uku ƙwayar cutar ta ragu da 20%. Kuma asarar abubuwan busassun na yin 0.7-1% a kowace rana lokacin da danshi daga tarin hatsi ya kasance 37% (Ginzburg, 1973).

Mahimman dalilai a cikin ingantaccen amfani da bushewa a cikin aikin gona shine samar da ingantaccen hatsi, ƙaruwar faɗin bandwidth na raka'a, da kuma rage farashin kuzari. Tushe don inganta tasirin masu bushewa a yanzu a harkar noma shine tabbatar da isasshen kuma tsayayyen danshi daga mita mai cubic a kyamarorin masu busar hatsi. Ofaya daga cikin dalilan da ke hana hakan shi ne cewa sassan sanyaya, waɗanda aka gina a cikin ramin bushewa, ba su ƙirƙirar yanayi mafi kyau don cikakken sanyaya hatsi kuma don haka rage ƙimar tasirin sandar bushewa da cire danshi daga mita mai siffar cubic na kamarar.

Tun lokacin da noman alkama na shekara ta 2010 ya nuna yanayin ci gaba mai karko: yankin amfanin gona ya karu da kashi 17%, yawan amfanin ƙasa ya karu da 25%, kuma yawan amfanin ƙasa - da 52%. A cikin 1 ga Janairu a shekarar 2012 Kazakhstan tana da silos 258 tare da karfin ajiya 14 dubu 771.3 tan da kuma lifta masu karfin ajiya tan 14 127.8 tan. Ofara yawan amfanin ƙasa da girbin girbi na buƙatar haɓaka fasahar bushewa don kauce wa asarar amfanin gona da kiyaye ƙimar hatsi.

Hanyar mafi hangen nesa don bushewar hatsi da cire danshi shine Hanyar dumama wuta wanda ya rage saura karatu kuma da wuya ake amfani dashi a aikace saboda ƙananan ajizanci a cikin fasahar masana'antun masu saurin mita. Kodayake induction dumama kayan aiki samarwa a halin yanzu yana haɓaka kuma yin amfani da shi aikin bushewar hatsi ya zama mafi kyau idan aka kwatanta da hanyoyin dumama na gargajiya (Zhidko, 1982).

A halin yanzu ana amfani da dumama na shigar da wuta don yin taurin ƙarfe na kayan ƙarfe, ta hanyar dumama don gurɓataccen filastik (ƙirƙira, bugawa, latsawa, da sauransu), narkewar ƙarfe, maganin zafi (annealing, tempering, normalizing, quenching), walda, walda, soldering , karafa Ana amfani da zafin shigarwa kai tsaye don dumama kayan aikin fasaha (bututun ruwa, tankuna, da sauransu), dumama ruwa, bushewar sutura da kayan aiki (misali, itace). Mafi mahimmancin mahimmanci na shigarwar dumama shine mita. Ga kowane tsari (hardewar ƙasa, ta hanyar dumama) akwai mafi kyawun zangon mita, yana samar da mafi kyawun fasaha da tattalin arziƙi. Ana amfani da mita daga 50Hz zuwa 5 MHz don zafin shigarwa.

Fa'idodin dumama wutar shigar da abubuwa kamar haka:

- Shigar da wutar lantarki kai tsaye cikin jikin dumama yana ba da damar aiwatar da kayan aikin kai tsaye, don haka ƙimar dumama take

- Shigar da wutar lantarki kai tsaye cikin jikin dumama baya bukatar na'urorin tuntuba. Wannan yana da amfani don layin atomatik

- Lokacin da kayan ɗumama abu ne na lantarki, misali hatsi, to ana rarraba wutar a ko'ina cikin ƙimar kayan dumama wuta. Sakamakon haka, wannan hanyar shigarwa tana samar da dumama cikin sauri

- Heatingarfin zafin ciki a cikin mafi yawan lokuta na iya haɓaka haɓaka da haɓaka yanayin aiki. Ana iya ɗaukar na'urar haɓaka a matsayin nau'i na mai canzawa, lokacin da aka haɗa winding na farko (inductor) zuwa tushen wutar AC, kuma kayan ɗumama suna matsayin na biyu

Rage farashin duk girkin yana buƙatar haɓakawa da aiwatarwa mai sauƙi a cikin zafin shigar da ƙirar ƙira.

Babban banbanci tsakanin shigar da wuta daga hanyoyin gargajiya na bushewa ya ta'allaka ne a kan dumama dumama. Zafin ya ratsa cikin samfurin (kayan) ba daga farfajiyar ba; an kafa shi a cikin dukkanin girma a lokaci ɗaya, wannan tsari yana ba da damar bushe hatsi yadda ya kamata tare da ƙarancin kuzari. Ko rarraba danshi yana faruwa ne a busasshen abu yayin aikin shigar da dumama. Uunƙwasawa baya ɗaukar canja wurin zafi daga hita zuwa abu. Yayin amfani da wasu hanyoyin bushewa yana buƙatar ɗumfa iska, sa'annan canja wurin zafi daga iska mai zafi zuwa abu. A kowane mataki - zafin iska, da jigilar sa, da canja wurin zafi zuwa kayayyaki - ba za a iya rasa asarar zafin ba.

A halin yanzu kamfanoni a Kazakhstan kusan basa amfani da masu sanya wutar wuta saboda suna da tsada sosai. Tsohon fitila model na Injin dumama wuta sun tsufa kuma ba'a kera su ba.

Bushewar hatsi ta hanyar shigar da dumama. Bushewa a cikin fadowa fadowa

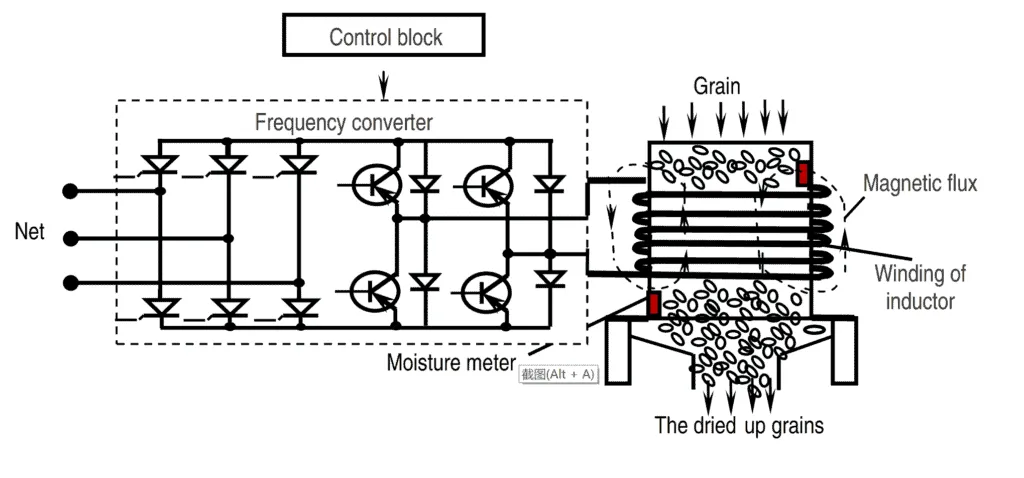

Muna ba da shawarar hanyar shigar da dumama ta bushewar hatsi (Hoto na 1) inda kayan hatsi suka wuce, wanda ke dauke da karfin nauyi, ta hanyar busar shaft. A saman busassun hatsi ana ɗora su ta hanyar masu ɗauke da guga ko wasu na'urori na safara; sannan hatsi ya shiga cikin hasumiyar bushewa. A cikin kyamara ta hasumiyar bushewa, inductor, wanda aka haɗa shi da mai sauya mitar, yana ƙirƙirar filin lantarki (maɗaukaki) na maɗaukaki.

Bushewa a cikin fadowa Layer. Faɗuwar faɗuwar ƙasa tana wakiltar rafin hatsi mai motsi da aka sauke sosai, wanda aka sashi ta hanyar haɓakar iskar gas zuwa sama (braking aerodynamic). Haɗin gaskiya na hatsi yana ƙaruwa a yayin motsi. Bushewa a cikin dakatar Layer. An sami yanayin hatsi da aka dakatar a cikin haɓakar iskar gas lokacin ƙaruwar saurin samar da wuta. A cikin aikin dukkan yanayin hatsi yana da hannu don zafi da musayar danshi tare da iskar gas. Lokacin zaman hatsi a cikin bututun pneumo bai wuce secondsan daƙiƙoƙi ba; zafin jiki na bushewa wakili sa 350-400 ° C. Koyaya, raguwar danshi yakai kashi kashi. Sabili da haka, ana amfani da kayan aiki tare da yadudduka masu nauyin nauyi ba kamar bushewa daban ba, amma azaman kayan haɗin bushewa mai ɗakuna da yawa.

Kammalawa

A yau kamfanonin aikin gona da lifta suna da kayan aiki mafi yawa ta masu bushewar shaft kai tsaye. Wadannan busassun suna ba da shawarar rashin daidaito a dumama da bushewar hatsi, wanda hakan ke haifar da tsadar bushewar thermal. Babban dalili anan shine ajizanci wajen samarda waken bushewa da iska mai shayarwar yatsun hatsi.

Yanayi mai mahimmanci don ingancin aiki na busassun hatsi shine ingantaccen sanyaya busasshiyar hatsi. Dangane da tsari an tsara na'urorin sanyaya masu busar hatsi ta yadda zafin jikin hatsin a lokacin fitarwa bazai wuce yanayin zafin iska na yanayi sama da 10 ° C ba. Koyaya, a aikace wannan ƙimar ta kai fiye da 12 ° C lokacin da zafin iska ya fi 15 ° C. Hakanan masu busar da hatsi na zamani suna samar da rashin daidaito sosai a cikin sanyaya nau'ikan hatsi na mutum. A cikin tattaunawar da aka tattauna game da shigar da bushewar dumama na iya zama hanya mafi dacewa dangane da yawan aiki, inganci da ingancin farashi.

References

Baum, A., 1983. bushewar hatsi [a Rasha], Moscow: Kolos

Ginzburg, A., 1973. Mahimman abubuwa na ka'ida da fasaha wajen bushewar kayan abinci [a cikin Rasha], Moscow: Masana'antar abinci

Zhidko, V., 1982. bushewar hatsi da busassun hatsi [a cikin Rasha], Moscow: Kolos