Menene curing curing?

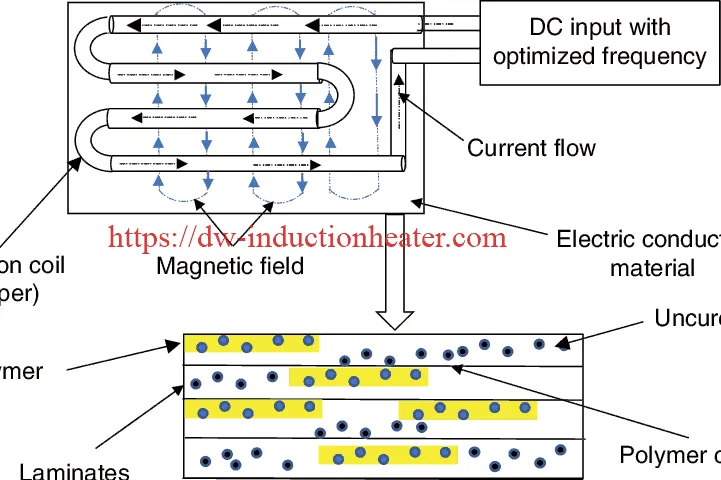

Ta yaya induction curing ke aiki? A taƙaice, ƙarfin layi yana jujjuya zuwa madaidaicin halin yanzu kuma ana isar da shi zuwa gaɓar aiki wanda ke haifar da filin lantarki a cikin coil. Yankin da ke da epoxy akansa na iya zama ƙarfe ko semiconductor kamar carbon ko graphite. Don warkar da epoxy akan abubuwan da ba su da ƙarfi kamar gilashi, ana iya amfani da mai ɗaukar hoto na lantarki don canja wurin zafi zuwa abin da ba ya daɗawa.

Menene fa'idodin warkarwa na induction?

Adhesives na epoxy guda ɗaya wanda aka warkar da zafi na iya amfani da zafi daga tushe daban-daban. Mafi yawanci shine tanda amma ana amfani da bindigogin iska mai zafi, faranti da gasa da kuma maganin induction. Maganin shigar da ƙara zai iya rage adadin lokacin da ake buƙata don warkar da epoxy da rage tasirin zafi akan abubuwan da ke kewaye kamar yadda dumama shigar da ke isar da zafi daidai ga yankin mannewa.

Shin shigar da magani zaɓi ne mai kyau ga aikace-aikacena?

Samar da ku induction dumama kayan aiki ƙwararre da bayanan masana'anta na mannen epoxy akan batutuwa masu zuwa zasu taimaka musu wajen ba da mafi kyawun shawarwarin.

1. Materials ko substrates ana bonded - Fahimtar abin da substrates ne zai taimaka wajen sanin dumama kudi da kuma ikon da ake bukata don warkar da m. Misali zafi na ƙarfe tare da ƙarancin ƙarfin da ake buƙata don dumama aluminum.

2. Girman abubuwan da aka haɗa - Ƙananan sassa suna buƙatar mafi girma mita don ingantaccen dumama. Manyan wurare suna amfana daga ƙananan mitar.

3. Abubuwan buƙatun Epoxy - Akwai min/max kofa don magance epoxy. Matsakaicin zafin jiki da ake buƙata don aiwatar da magani da matsakaicin zafin jiki da aka yarda kafin rushewar epoxy.

Gabatarwar Magani don Haɗa Chip ɗin Quartz zuwa Silinda Karfe

Wani kamfani a cikin masana'antar kera motoci yana neman tsarin dumama shigar da zai iya kaiwa zafin 175°C (347°F) kuma ya riƙe shi cikin tsananin juriyar +/- 3 C. Ƙarƙashin ƙarewa zai yi zafi da silinda na ƙarfe don warkar da abin ɗamara don haɗa guntun quartz. Dumamar shigar da ita hanyar da aka fi so saboda tana ba da sauri, sarrafawa da ƙarin dumama iri ɗaya.

Industry: Mota

Kayan aiki: DW-UHF-10kW tsarin dumama wuta ana bada shawarar don wannan aikace-aikacen warkewa don haɓaka sama da riƙe zafin da ake so.

tsari:

Makasudin wannan aikace-aikacen warkarwa na induction shine don ƙona bangarorin biyu na silinda na ƙarfe wanda shine 1.064” (2.70 cm) OD, 7.25” (18.41 cm) tsayi tare da yankin zafi 1” (2.54 cm) har zuwa 175 C (347°) F) kuma riƙe wannan zafin na tsawon daƙiƙa 60 don aiwatar da aikace-aikacen haɗin gwiwa. An kai zafin da ake so a cikin daƙiƙa 13. An yi amfani da mai sarrafa zafin jiki irin K don auna zafin jiki.

Gabatarwar Magani don Haɗa Chip ɗin Quartz zuwa Silinda Karfe