Induction Brazing Tubes Aluminium tare da High Frequency Induction Heating

Yankunan aikace-aikacen labari na shigar da dumama yana buƙatar nazarin rarraba yanayin zafin jiki a cikin abubuwan da aka zafafa la'akari da abubuwan da suka dace da kaddarorin kayan. Hanyar iyakantacciyar hanya (FEM) tana ba da kayan aiki mai ƙarfi don yin irin waɗannan nazarin da haɓaka abubuwan ɗimamawa ta hanyar haɗawa da ƙididdigar lantarki da zafin jiki.

Babban manufar wannan gudummawar shine a nuna yiwuwar yin amfani da fasahar brazing ta dace, ingantacciya da inganci don kera masu tara hasken rana dangane da kwafin adadi da gwaje-gwajen da aka yi.

Shirya matsala

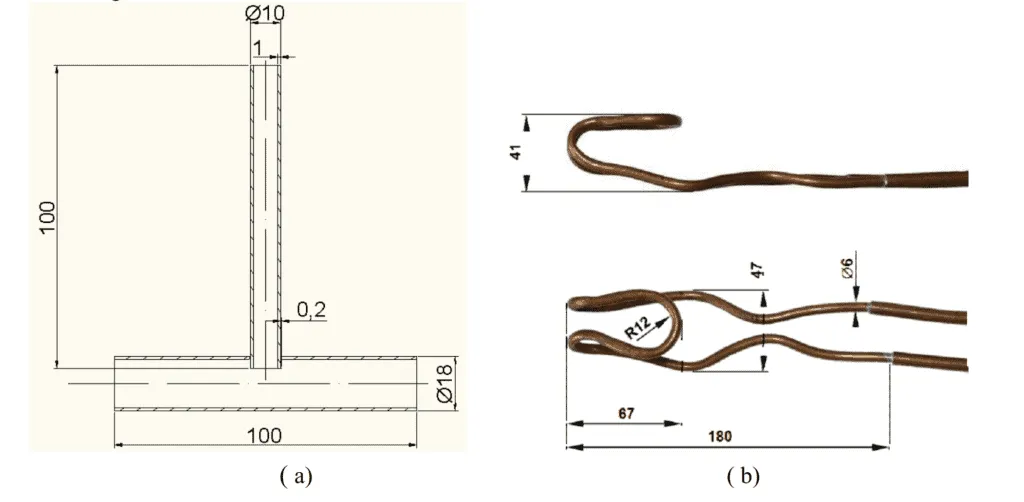

Wannan aikin yana aiki ne da ƙirar abubuwan da aka tsara don masu tara hasken rana waɗanda suka dace da aikin brazing, wato ɓangarorin tattara tubing (Fig. 1a). Tubes ana yin su ne daga Al alloy na nau'in AW 3000 tare da kayan aikin sunadarai da aka bayar a cikin Tebur 1. Don ƙarfafawa, ana amfani da alli na nau'in Al 104 (Table 2) tare da ruwan kwalliyar Braze Tec 32/80 wanda ragowar ba su da -zama mai lalacewa. Matsakaicin zafin jiki tsakanin daskararriya da yanayin ruwa na Al 104 mai hade gwal ya fito ne daga 575 ° C zuwa 585 ° C. Temperaturearfin zafin jikin bututun yana da 650 ° C.

Tebur 1 Kayan aikin sinadarai na allurar AW 3000 [wt. %]

| Si | Fe | Cu | Mn | Mg | Zn | Cr | Al |

| 0.05-0.15 | 0.06-0.35 | max 0.1 | 0.3-0.6 | 0.02-0.20 | 0.05-0.3 | max 0.25 | balance |

Tebur na 2 na kayan haɗin keɓaɓɓen ƙarfe na nau'in Al 104 [wt. %]

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 11-13 | 0.6 | max 0.3 | 0.15 | 0.1 | 0.2 | max 0.15 | balance |

Tsarin takalmin gyaran kafa yana daukar aikin dumama wuta. Wajibi ne a tsara tsarin dumama yanayi ta yadda za a sami yanayin zafin nama a cikin yankin haɗin gwiwa (ƙarfe mai ƙarfe - ƙarfe mai ƙulla) a lokaci guda. Daga wannan ra'ayi, zaɓin da ya dace da murfin shigar da abubuwa, lissafinsa da sigogin aiki (galibi mitar da tushen asalin) yana da mahimmanci. An nuna fasali da girma na tsararren jan ƙarfe mai jan ruwa mai jan ƙarfe a cikin hoto 1b

An kimanta tasirin sigogi masu dacewa na dumama wuta akan rarraba yanayin zafin jiki a cikin sassan brazed ta amfani da kwafin adadi na ƙwanƙwasawa mai amfani da lambar shirin ANSYS 10.0.

Misalin kwaikwayo

Dangane da hanyoyin magance matsalolin electromagnetic da na yanayi masu zafi ta hanyar amfani da FEM ta amfani da software na ANSYS 10.0 [3-5], an tsara samfurin kwaikwaiyo na aikin dumama zafin nama na brazing ciki har da yanayin yanayi, na zahiri, da na farko da na iyaka. Babban manufar yin kwafin lambobi shine ayyana mafi kyawun sigogi na shigar dumu dumu (mitar da kuma tushen asalin yanzu) don cimma nasarar rarraba zafin jiki a yankin haɗin haɗin gwiwa.

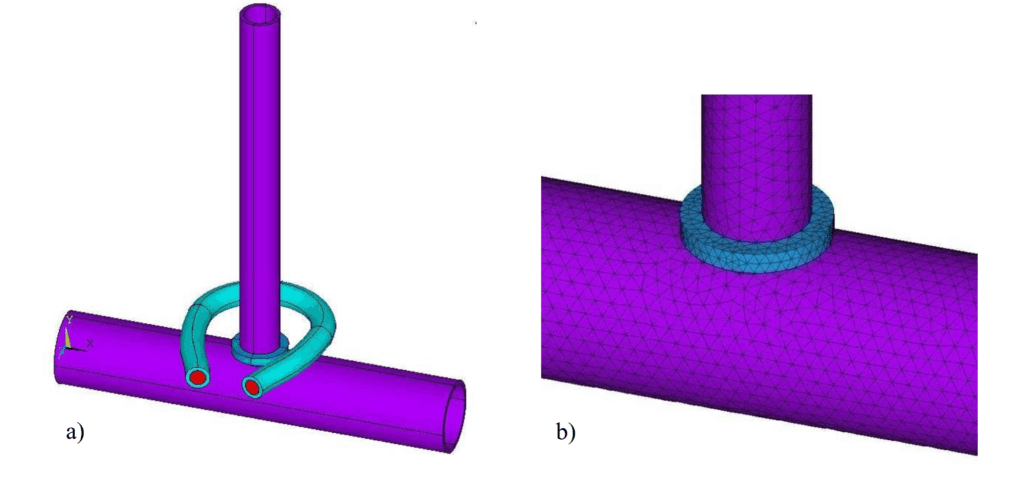

Shawarar 3D-samfurin (Fig. 2) don nazarin lantarki ya ƙunshi samfurin tubes, ƙarfe brazing, murfin shigar da ruwa mai sanyaya da iska mai kewaye (wanda ba a nuna a cikin hoto na 2 ba). A cikin nazarin zafin jiki, kawai ana ɗauke da bututu da ƙarfe mai ƙyalli. Detailarin dalla-dalla na raga da aka samo daga layin layi, abubuwa 8-kumburi a cikin yankin haɗin haɗin gwiwa an kwatanta a cikin siffa 2b.

Hoto na 2 a) Tsarin geometrical don nazarin electromagnetic ba tare da kewaye da iska ba da kuma b) dalla-dalla na raga 3D da aka samar a yankin haɗin haɗin gwiwa. Dogaro da zafin jiki na kayan lantarki da na zafin jiki na kayan haɗin 3000 na AW 104 da Al 6 brazing alloy an samo ta amfani da JMatPro software [XNUMX]. Wadannan daga gaskiyar cewa kayan da aka yi amfani da su ba magnetic ba ne, haɓakar dangin su µr = 1.

Yanayin zafin jiki na farko na kayan brazed ya kasance 20 ° C. Kamatattun lambobin lantarki da na zafin jiki a kan iyakokin saman kayan da ake tsammani. Yawan madogarar tushe a cikin murfin shigar ya kamata ya zama 350 kHz. An bayyana ƙimar tushen asalin daga tazarar daga 600 A zuwa 700 A. Sanyayawar bututu masu ƙwanƙwasa ta hanyar isar da ruwa kyauta da iska zuwa iska tare da zafin jiki na 20 ° C. Haɗin haɓakar ƙarfin canja zafi wanda ya dogara da yanayin zafin jiki na ɓangarorin brazed an bayyana. A cikin hoto na 3, rarraba yanayin zafin jiki a cikin abubuwan haɗin bayan nasarar nasarar yanayin zafin jiki da ake buƙata a cikin yankin haɗin gwiwa ana nuna su don ƙimar zaɓaɓɓun hanyoyin ruwan da ake amfani da su a cikin ƙin murhun wuta. Lokacin 36 sakan ta amfani da tushen asalin 600 A da alama yana da tsayi sosai. Saurin zafi mai amfani da tushen asalin 700 A ba zai iya isa ga narkewar gwal ɗin ƙirar Al 104 ba. A cikin wannan dalilin asalin da yake kusan matakin 620 A zuwa 640 A ana ba da shawarar da zai kai ga lokacin yin ƙarfin gwiwa daga sakan 25 zuwa 27.5 ……