Fasahar Fassara ta Induction

Shafin Farko na Gudanarwa | Shaidar

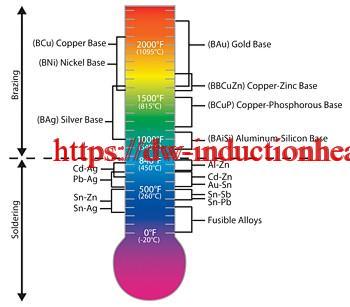

Brazing da soldering sune tafiyar matakai na shiga cikin irin wannan abu ko kayan aiki marasa amfani ta amfani da kayan aiki mai jituwa. Gyara karafa sun haɗa da gubar, tin, jan karfe, azurfa, nickel da allo. Sai kawai alloy yana narkewa da kuma karfafawa a lokacin wadannan matakai don shiga kayan aikin gine-gine. An ƙera kayan haɓaka a cikin haɗin gwiwa ta hanyar aiki na capillary. Ana gudanar da matakai na ƙaddamarwa a karkashin 840 ° F (450 ° C) yayin da ake gudanar da aikace-aikacen ƙarfafawa a yanayin zafi sama da 840 ° F (450 ° C) har zuwa 2100 ° F (1150 ° C).

Nasarar wadannan matakai na dogara ne akan zanewar taron, rashin daidaituwa a tsakanin ɗakunan da za a haɗa, tsabta, sarrafa tsarin da kuma zaɓi na kayan aiki da ake buƙata don aiwatar da tsari mai maimaitawa.

Ana iya samun tsabta ta hanyar gabatar da haɗari wanda yake rufewa da kuma narke ƙazanta ko kuma oxides da ke motsa su daga haɗin gwiwa.

Yawancin ayyuka yanzu ana gudanar da su a cikin yanayi mai sarrafawa tare da bargo na inert gas ko haɗuwa da iska mai aiki / gass masu aiki don kiyaye aikin da kawar da buƙatar sauyi. Wadannan hanyoyin an tabbatar dasu akan nau'ikan kayan abubuwa daban-daban da kuma bangarorin da suke maye gurbinsu ko yabawa fasahar makera ta yanayi tareda dacewa da lokaci - tsarin yanki guda daya.

Matsalar Gidan Gida

Ƙarƙashin gyaran fuska na ƙarfe yana iya zuwa a cikin nau'i-nau'i, siffofi, masu girma da allo da suka dogara da amfani da su. Ribbon, ƙirar da aka riga aka rigaya, manna, waya da kuma washers na farko sun kasance kawai daga cikin siffofi kuma sunada allo wanda za'a iya samuwa.

Ƙaƙarin yin amfani da takamaiman kayan aiki da / ko siffar yana dogara ne akan kayan iyaye don haɗawa, sanyawa a lokacin sarrafawa da kuma sabis na sabis wanda aka ƙaddara samfurin karshe.

Clearance shafi tasiri

Daidaitawa a tsakanin fayilolin da za a haɗu don haɗuwa ya ƙayyade adadin ƙafafun ƙarfe, aiki na capillary / shigarwa cikin mota kuma daga baya ƙarfin haɗin gamawa. Mafi kyawun yanayin da ake amfani da shi na kayan ado na azurfa shine 0.002 inci (0.050 mm) zuwa 0.005 inci (0.127 mm) cikakken izinin. Aluminum shine yawanci 0.004 inci (0.102 mm) zuwa 0.006 inci (0.153 mm). Ƙididdigar girma har zuwa 0.015 inci (0.380 mm) yawancin lokaci bai isa ya zama aiki na capillary don cin nasara ba.

Yin ƙarfin tagulla tare da jan ƙarfe (a sama da 1650 ° F / 900 ° C) yana buƙatar haɗin kai haɗin kai ya kasance cikakke kuma a wasu lokuta danna fitarwa a yanayin zafi na yanayi don tabbatar da haɗin haɗin haɗin haɗin gwiwa yayin da zafin fuska.

Sanarwar Kayan Kayan Gida

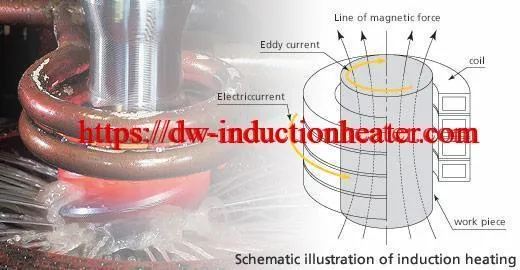

Tsarin hanyoyi suna samar da hanyar da ta dace da kuma dacewa da sauri don yin tasiri da zafin wuri na wani taro. Dole ne a ba da la'akari da zaɓin wutar lantarki da yawan aiki, ƙarfin wutar lantarki (kilowatt amfani da square inch), lokaci mai zafi, da kuma sigina na zane don samar da zurfin da ake buƙata na dumama a wani takalmin gyaran fuska.

Ƙarƙashin ƙarancin ba shi da alamar kullawa ta hanyar tsarin juyin halitta. Rashin wutar lantarki shi ne tushen AC don murfin shigarwa wanda ya zama maɓallin farko na mai juyawa yayin da bangaren ya zama mai tsanani shi ne na biyu. Ƙungiyar aikin ta da kayan kayan gine-ginen 'kayan lantarki ya zama abin ƙyama ga abin da ke gudana a cikin taron.

Samun wucewa ta yanzu ta hanyar jagorancin lantarki (aikin) yana haifar da dumama kamar yadda halin yanzu yana fuskantar juriya don gudana. Wadannan asarar suna da raguwa a cikin aluminum, jan ƙarfe da allo. Wadannan kayan da ba kayan aiki suna buƙatar ƙarin ƙarfin da zafin zafi fiye da takalmin carbon carbon.

A halin yanzu yana sa ran ya gudana a farfajiyar. Ma'ana tsakanin mita na yanzu da zurfin da yake shiga cikin sashi an san shi azaman zurfin tunani. Sashe na diamita, nau'in kayan abu da bangon kauri na iya samun tasiri akan zafin jiki daidai bisa la'akari da zurfi.