HLQ Tsarin suma sune tsarin kara darajar da zasu dace da kai tsaye a cikin masana'antar kera, rage gogewa, sharar gida, kuma ba tare da buƙatar masu amfani da wutar ba. Za'a iya daidaita tsarin don sarrafawa na hannu, mai sarrafa kansa-da-kai, har zuwa gabaɗaya zuwa tsarin sarrafa kansa. HLQ induction brazing da siyarwar tsarin tsarin akai-akai suna ba da gidajen abinci mai tsabta, ba tare da yaduwa ba don mahara da yawa da suka hada da layin mai, masu musayar wuta, masu rarraba gas, abubuwa da yawa, kayan aiki carbide, da ƙari.

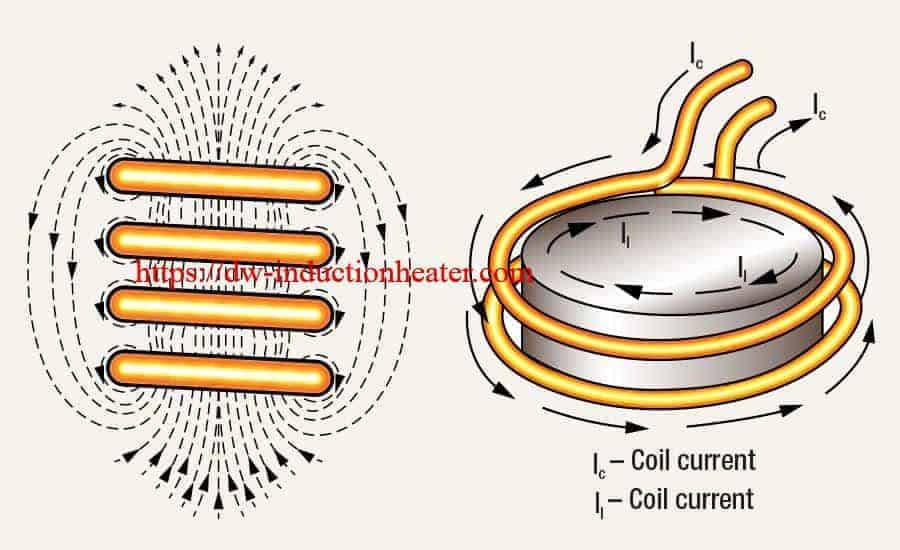

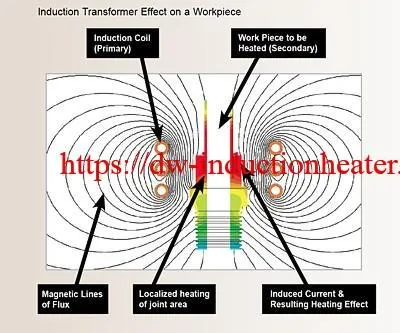

Ka'idojin Induction Brazing & Soldering

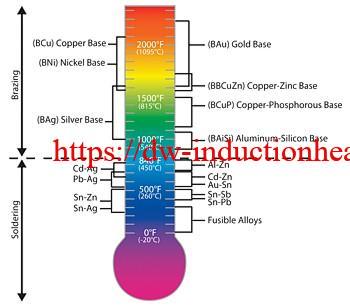

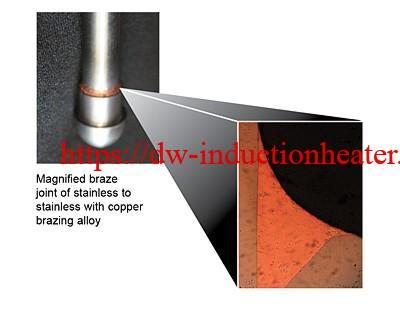

Brazing da soldering sune tafiyar matakai na shiga cikin irin wannan abu ko kayan aiki marasa amfani ta amfani da kayan aiki mai jituwa. Gyara karafa sun haɗa da gubar, tin, jan karfe, azurfa, nickel da allo. Sai kawai alloy yana narkewa da kuma karfafawa a lokacin wadannan matakai don shiga kayan aikin gine-gine. An ƙera kayan haɓaka a cikin haɗin gwiwa ta hanyar aiki na capillary. Ana gudanar da matakai na ƙaddamarwa a karkashin 840 ° F (450 ° C) yayin da ake gudanar da aikace-aikacen ƙarfafawa a yanayin zafi sama da 840 ° F (450 ° C) har zuwa 2100 ° F (1150 ° C).

Nasarar wadannan matakai na dogara ne akan zanewar taron, rashin daidaituwa a tsakanin ɗakunan da za a haɗa, tsabta, sarrafa tsarin da kuma zaɓi na kayan aiki da ake buƙata don aiwatar da tsari mai maimaitawa.

Nasarar wadannan matakai na dogara ne akan zanewar taron, rashin daidaituwa a tsakanin ɗakunan da za a haɗa, tsabta, sarrafa tsarin da kuma zaɓi na kayan aiki da ake buƙata don aiwatar da tsari mai maimaitawa.

Ana iya samun tsabta ta hanyar gabatar da haɗari wanda yake rufewa da kuma narke ƙazanta ko kuma oxides da ke motsa su daga haɗin gwiwa.

Abun ciki Brazing Filler Materials

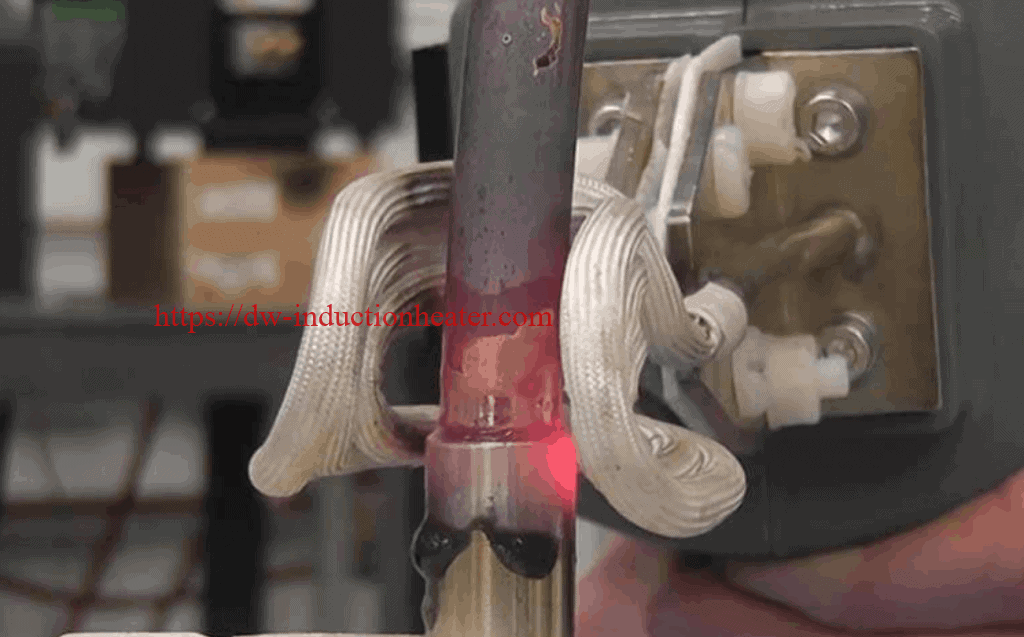

Induction Brazing filler karafa na iya zuwa ta fannoni daban-daban, siffofi, masu girma dabam da kuma alƙirami gwargwadon amfanin da aka yi niyya. Ribbon, zoben da aka sanya, waƙa, waya da kuma wankin da aka riga aka yi yan su ne kaɗan daga cikin sifofi kuma ana iya samin allo.

Ƙaƙarin yin amfani da takamaiman kayan aiki da / ko siffar yana dogara ne akan kayan iyaye don haɗawa, sanyawa a lokacin sarrafawa da kuma sabis na sabis wanda aka ƙaddara samfurin karshe.

Yawancin ayyuka yanzu ana gudanar da su a cikin yanayi mai sarrafawa tare da bargo na inert gas ko haɗuwa da iska mai aiki / gass masu aiki don kiyaye aikin da kawar da buƙatar sauyi. Wadannan hanyoyin an tabbatar dasu akan nau'ikan kayan abubuwa daban-daban da kuma bangarorin da suke maye gurbinsu ko yabawa fasahar makera ta yanayi tareda dacewa da lokaci - tsarin yanki guda daya.

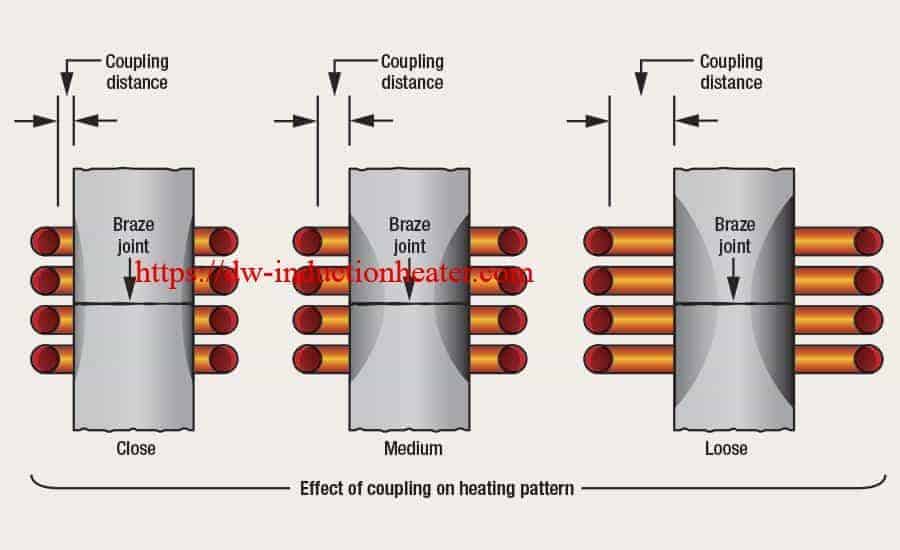

Clearance shafi tasiri

Daidaitawa a tsakanin fayilolin da za a haɗu don haɗuwa ya ƙayyade adadin ƙafafun ƙarfe, aiki na capillary / shigarwa cikin mota kuma daga baya ƙarfin haɗin gamawa. Mafi kyawun yanayin da ake amfani da shi na kayan ado na azurfa shine 0.002 inci (0.050 mm) zuwa 0.005 inci (0.127 mm) cikakken izinin. Aluminum shine yawanci 0.004 inci (0.102 mm) zuwa 0.006 inci (0.153 mm). Ƙididdigar girma har zuwa 0.015 inci (0.380 mm) yawancin lokaci bai isa ya zama aiki na capillary don cin nasara ba.

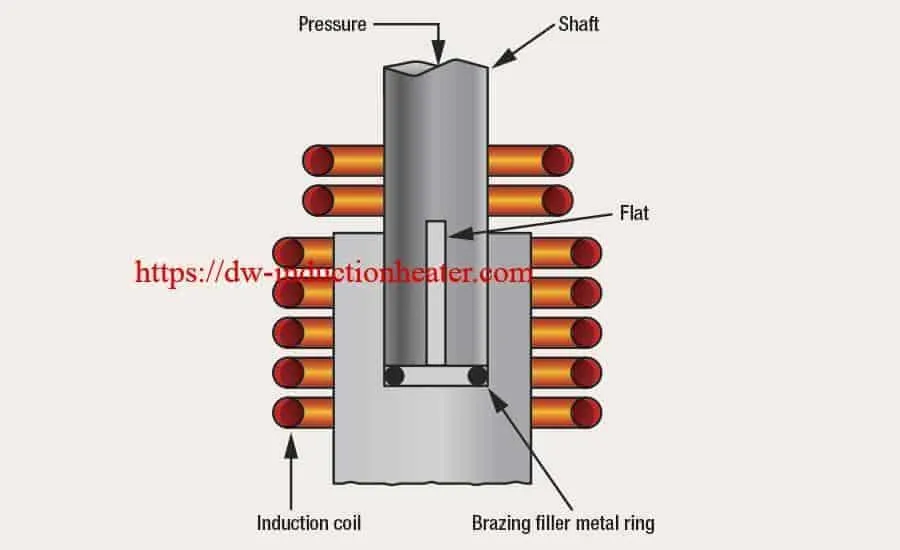

Yin ƙarfin tagulla tare da jan ƙarfe (a sama da 1650 ° F / 900 ° C) yana buƙatar haɗin kai haɗin kai ya kasance cikakke kuma a wasu lokuta danna fitarwa a yanayin zafi na yanayi don tabbatar da haɗin haɗin haɗin haɗin gwiwa yayin da zafin fuska.

Tsarin dumamar yanayi ya tabbatar da kasancewa mai mahimmanci taimako a cikin hada hadar saboda dalilai da yawa. Takamaiman saurin aiki da madaidaicin sarrafa zafi yana ba da yiwuwar karkatar da aka keɓance na kayan ƙarfi mai ƙarfi ba tare da canza kayan kayan ba. Hakanan yana ba da izinin yin amfani da kayan wuya irin su aluminium da jerin abubuwa, bra bray-bracing da soldering na kusancin gidajen abinci.

Za'a iya sauƙaƙe kayan aikin inshora a cikin ƙarfin bracing da siyarwa don tsarin layin samarwa, ba da izinin tsarin kayan aiki a cikin layin babban taro, kuma idan ya cancanta, dumama ta hanyar nesa. Akai-akai, shigo da bra bra da soldering yana ba da izinin rage adadin kayan haɗin, tare da ƙarancin dumu-dumu na abubuwan gyaran abubuwan haɓaka tsawon rayuwa da kuma riƙe daidaito cikin abubuwan da za a haɗa su. Tunda masu aiki basu buƙatar jagorantar tushen aikin dumama, hannayen biyu an bar su biyu don shirya babban taro don shiga.

HLQ shigowa brazing kayan aiki yana ba da inganci, daidaito, daidaitawa ta kayan aiki, da sauyawa akan sauƙin kayan aiki don buƙatu iri iri. Radyne induction brazing da siyarwar layin samarwa yana bayar da daidaitattun hanyoyin magance bra bra:

HLQ shigowa brazing kayan aiki yana ba da inganci, daidaito, daidaitawa ta kayan aiki, da sauyawa akan sauƙin kayan aiki don buƙatu iri iri. Radyne induction brazing da siyarwar layin samarwa yana bayar da daidaitattun hanyoyin magance bra bra:

aluminum

Copper

Brass

bakin karfe

Carbide

Kuma mafi…