Induction Aluminum Brazing tare da Taimakon Kwamfuta

Uunƙwasa ƙarfen ƙarfe ya zama ruwan dare gama gari a masana’antu. Misali na yau da kullun shine ƙwanƙwasa bututu daban-daban ga jikin musanyar wuta. Da ƙin murhun wuta yadu amfani da wannan nau'in aikin ba mai kewayewa bane, wanda za'a iya kiran shi da salon "Horseshoe-hairpin". Don waɗannan murfin, filin magnetic da sakamakon rarrabuwa na yanzu sune 3-D a dabi'a. A cikin waɗannan aikace-aikacen, akwai matsaloli tare da haɗin haɗin kai da daidaito na sakamakon daga sashi zuwa sashi. Don magance ɗayan irin wannan matsala don babban masana'antar kera motoci, an yi amfani da shirin kwayar komputa na Flux3D don nazarin tsari da ingantawa. Ingantaccen abu ya haɗa da sauya murfin shigar da maganadisu. Sabbin abubuwan shigarwa, wadanda aka tabbatar dasu ta hanyar gwaji a dakin gwaje-gwaje, suna samarda bangarori masu hade da inganci a wurare da yawa na samarwa.

Kowace mota tana buƙatar masu musayar zafin wuta daban-daban (murhunan hurawa, masu fitar da ruwa, masu sanyawa, radiators, da sauransu) don sanyaya cikin wutan lantarki, kwandishan, sanyaya mai, da sauransu. Mafi yawa daga cikin masu musayar zafin motar fasinja a yau an yi su ne da sinadarin aluminum ko na allo. Kodayake ana amfani da injin iri ɗaya don samfuran mota da yawa, haɗin haɗin na iya bambanta saboda fasali daban-daban a ƙarƙashin kaho. A saboda wannan dalili, ƙa'ida ce madaidaiciya ga masana'antun sassa don yin mambobin musayar zafin jiki da yawa na asali sannan kuma haɗa mahaɗa daban-daban a cikin aiki na biyu.

Jikin masu musayar zafin galibi sun ƙunshi firam ɗin firam, bututu da maƙun kan kan da aka ƙulla su a cikin murhu. Bayan ƙarfafawa, masu musayar zafin jiki an keɓance su don ƙirar motar da aka ba ta haɗawa ko dai tankunan nailan ko mafi yawan nau'ikan bututun aluminum da keɓaɓɓen haɗin. Wadannan bututun an hade su ko dai ta hanyar walda MIG, ta harshen wuta ko takalmin shigarwa. Dangane da brazing, ana buƙatar madaidaiciyar sarrafa zafin jiki saboda ƙaramin bambanci a yanayin narkewa da ƙwanƙwasawa na aluminium (20-50 C dangane da gami, ƙarfe da yanayin yanayi), haɓakar haɓakar zafin jiki na aluminum da kuma tazarar tazara zuwa wasu haɗin gwiwa a cikin aikin da ya gabata.

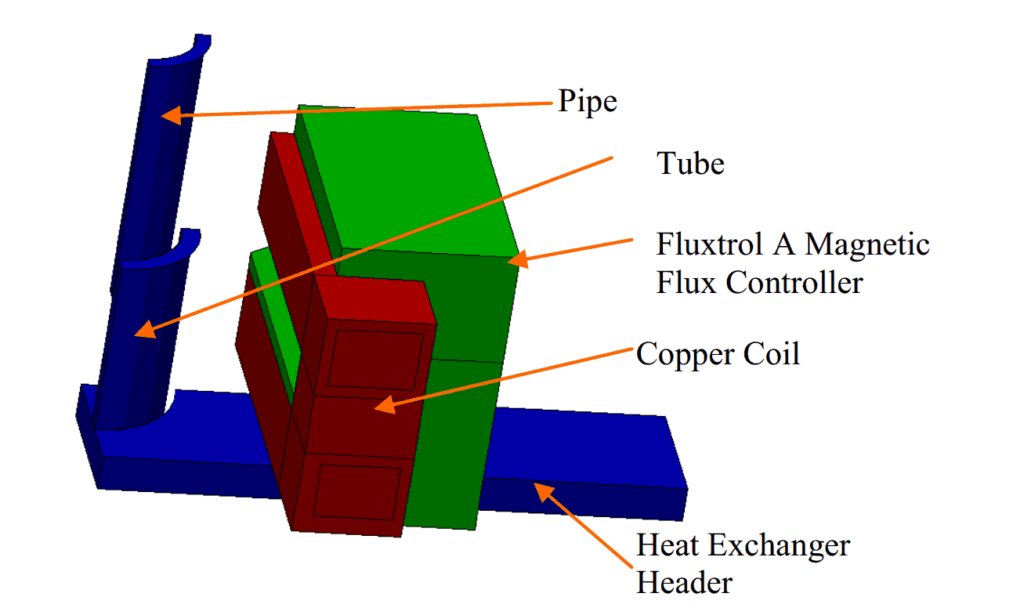

Ƙarƙashin ƙarewa hanya ce ta gama gari don yin kwalliya da bututu iri daban-daban don masu buga musayar zafi. Hoto na 1 hoto ne na wani shigar da brazing saiti don ƙarfafa bututu zuwa bututu kan taken musayar zafi. Dangane da abubuwan da ake buƙata don takamaiman dumama, fuskar murfin shigarwar dole ne ta kasance kusa da haɗin gwiwa don yin ƙarfin gwiwa. Sabili da haka ba za a iya amfani da keɓaɓɓiyar kewaya ba, saboda ba za a iya cire ɓangaren ba bayan haɗin haɗin ya yi ƙarfin gwiwa.

Akwai manyan hanyoyi guda biyu na shigar da abu da aka yi amfani dasu don kwalliyar waɗannan abubuwan haɗin gwiwa: masu salo irin na “clamshell” da “horsehoe-hairpin”. "Clamshell" inductors sunyi kama da inductors masu motsi, amma suna buɗe don ba da damar cire ɓangare. "Masu shigar dawakai-gashin gashi" masu siffofi sun yi kama da takalmin takalmin doki don ɗora kwatankwacin kuma ainihin murfin gashin gashi biyu ne a ɓangarorin biyu na haɗin gwiwa.

Amfanin yin amfani da inductor “Clamshell” shine cewa dumama yafi daidaito a kewaya kuma yana da sauƙin hango nesa. Rashin dacewar inductor "Clamshell" shine cewa tsarin inji da ake buƙata ya fi rikitarwa kuma manyan lambobin yanzu ba su da tabbas.

"Horseshoe-hairpin" inductors sun samar da tsarin 3-D mai rikitarwa fiye da "Clamshells". Amfani da salon "Horseshoe-hairpin" mai sakawa a ido shine cewa an saukaka yadda ake sarrafa bangaren.

Kwaikwayon komputa yana inganta ƙarfin gwiwa

Wani babban mai sana'ar musayar zafin yana fama da matsaloli masu inganci tare da sanya takalmin hadin gwiwa wanda aka nuna a cikin hoto na 1 ta hanyar amfani da mai salo irin na takalmin takalmin takalmin kafa. Haɗin katakon takalmin yana da kyau ga yawancin sassan, amma dumama zai iya zama daban ga wasu sassan, wanda zai haifar da karancin zurfin haɗin gwiwa, haɗin gwiwa mai sanyi da kuma filler ƙarfe wanda ke bin bangon bututu saboda yanayin zafi fiye da ƙasa. Ko da tare da gwajin kowane mai musayar zafin rana don kwararar abubuwa, wasu sassan har yanzu suna zubowa a wannan haɗin gwiwa a cikin sabis. Center for Induction Technology Inc. an ba ta kwangila don yin nazari da magance matsalar.

Thearfin wutar da aka yi amfani da shi don aikin yana da saurin sauyawa na 10 zuwa 25 kHz kuma ƙarfin da aka ƙaddara na 60 kW. A cikin tsarin takalmin motsa jiki, wani ma'aikaci ya girka zoben ƙarfe mai ƙara akan bututun kuma ya saka bututun a cikin bututun. Ana sanya mai musayar wuta akan rigar na musamman kuma yana motsawa cikin inductor na takalmin kofaton kafa.

An riga an riga an riga an shimfida dukkan yankin kerawa. Mitar da ake amfani da ita don zafafa sashin yawanci 12 zuwa 15 kHz ne, kuma lokacin ɗumi yana kusa da dakika 20. An tsara matakin ƙarfin tare da rage layin a ƙarshen zagayen dumama. Pyrometer na gani yana kashe wutar lokacin da zafin jiki a gefen baya na haɗin gwiwa ya kai ƙimar da aka saita.

Akwai dalilai da yawa da zasu iya haifar da rashin daidaito da masana'antar ke fuskanta, kamar bambancin haɗin haɗin (girma da matsayi) da rashin ƙarfi da canji (a cikin lokaci) wutar lantarki da hulɗar zafi tsakanin bututu, bututu, zoben filler, da sauransu. ba su da tabbas, kuma ƙananan bambancin waɗannan abubuwan na iya haifar da canjin yanayi daban-daban. Misali, zoben karfe mai bude mai iya budewa a wani bangare a karkashin karfin maganadisun lantarki, kuma za'a iya tsotar da karshen zoben ta hanyar daskararrun abubuwa ko kuma ba za'a sakasu ba. Abubuwan hayaniya suna da wahalar ragewa ko kawarwa, kuma maganin matsalar da ake buƙata yana ƙaruwa da ƙarfi na aikin gabaɗaya. Kwaikwayon kwamfuta kayan aiki ne mai tasiri don nazari da kuma inganta aikin.

Yayin kimantawa da tsarin karfafa gwiwa, an lura da karfi na karfin lantarki. A daidai lokacin da aka kunna wutar lantarki, takalmin takalmin doki a bayyane ya sami fadada saboda amfani da karfin lantarki. Sabili da haka, an ƙaddamar da mai haɓaka ta hanyar inji, haɗe da haɗa ƙarin faranti na gilashi (G10) wanda ke haɗa tushen murfin gashin biyu. Sauran zanga-zangar karfin wutar lantarki da aka gabatar shine sauyawar narkakken karfe wanda yake kusa da wuraren dake kusa da jan karfe inda karfin maganadisu yafi karfi. A cikin tsari na yau da kullun, ƙarfen filler yana rarrabawa gaba ɗaya a haɗin haɗin gwiwa saboda ƙarfin haɗari da nauyi wanda ya bambanta da wani tsari mara kyau inda ƙarfen filler zai iya fita daga haɗin haɗin ko ya hau sama ta saman bututun.

saboda aluminumarfafa sandar ƙarfe abu ne mai matukar rikitarwa, ba zai yiwu a yi tsammanin cikakken kwaikwaiyo na dukkanin jerin abubuwan da suka hadu da juna ba (electromagnetic, thermal, mechanical, hydrodynamic and metallurgical). Mafi mahimmancin tsari da sarrafawa shine ƙarni na tushen wutar lantarki, wanda aka bincika ta amfani da shirin Flux 3D. Dangane da mawuyacin yanayi na aiwatar da aikin brazing, an yi amfani da haɗin kwatancen kwamfuta da gwaje-gwaje don ƙirar tsari da haɓakawa.