induction dumama filastik granulator

description

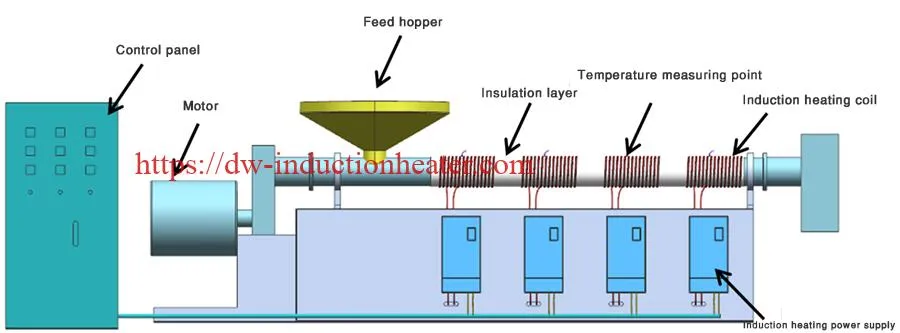

Taƙaitaccen Gabatarwa na dumama filastik granulator/filin filastik:

Ƙarƙashin ƙarewa filastik granulator/roba extrusion wani nau'i ne na dumama mai ceton makamashi. Yana da abũbuwan amfãni da yawa ciki har da gagarumin ceton makamashi, da sauri dumama up, high makamashi yadda ya dace, low ko sifili kiyayewa da dai sauransu Yana kuma iya rage yawan zafin jiki yanayi ta samar da yawa kasa zafi. Yayin shigar da tsarin dumama na'urar, ba za a haɗa da wasu manyan canje-canje ga tsarin sarrafa wutar lantarki ba.

A ina za a iya shigar da dumama filastik granulator / filastik extrusion?

A ina za a iya shigar da dumama filastik granulator / filastik extrusion?

An fi amfani da shi ga allura, extrusion; busa yin fim, waya zane, granulating da sake amfani da inji, da dai sauransu The samfurin aikace-aikace hada da fim, takardar, profile, albarkatun kasa da dai sauransu Ana iya amfani da dumama ganga, flange, mutu shugaban, dunƙule da sauran sassa na inji. Yana da kyau a cikin tanadin makamashi da sanyaya yanayin aiki.

Ƙarƙashin ƙarewa shi ne tsarin dumama wani abu mai sarrafa wutar lantarki (yawanci karfe) ta hanyar shigar da wutar lantarki, inda ake haifar da igiyar ruwa a cikin karfen kuma juriya ya kai ga dumama karfen Joule. Nadar shigar da kanta baya yin zafi. Abun da ke haifar da zafi shine abu mai zafi da kansa.

Me yasa kuma ta yaya induction dumama filastik granulator / filasta extrusion zai iya ceton kuzari?

A halin yanzu, yawancin injunan filastik suna amfani da hanyar dumama juriya ta al'ada, inda wayar juriya ta kasance mai zafi sannan kuma a canza wurin zafi zuwa ganga ta hanyar murfin dumama. zafi kusa da murfin dumama na waje yana ɓacewa zuwa iska wanda ke haifar da hauhawar yanayin yanayin.

Induction hita Technology inda high mita Magnetic filayen wanda ya sa ya zama mai zafi bu electro-magnetic field (EMF) da suke goga da juna.Lokacin da ganga da aka mai tsanani da zafi ne m, akwai sosai high zafi dace da mafi ƙarancin zafi hasara zuwa muhallin da tanadin makamashi zai iya kaiwa 30-80%.Saboda gaskiyar cewa induction coil baya haifar da wani zafi mai zafi haka kuma babu wata waya mai juriya da ke samun oxidized kuma ta sa injin ya ƙone, injin induction yana da sabis mai tsawo. rayuwa da kuma ƙarancin kulawa.

Menene fa'idodin induction dumama filastik granulator / filasta extrusion?

Menene fa'idodin induction dumama filastik granulator / filasta extrusion?

- Amfanin makamashi 30% -85%

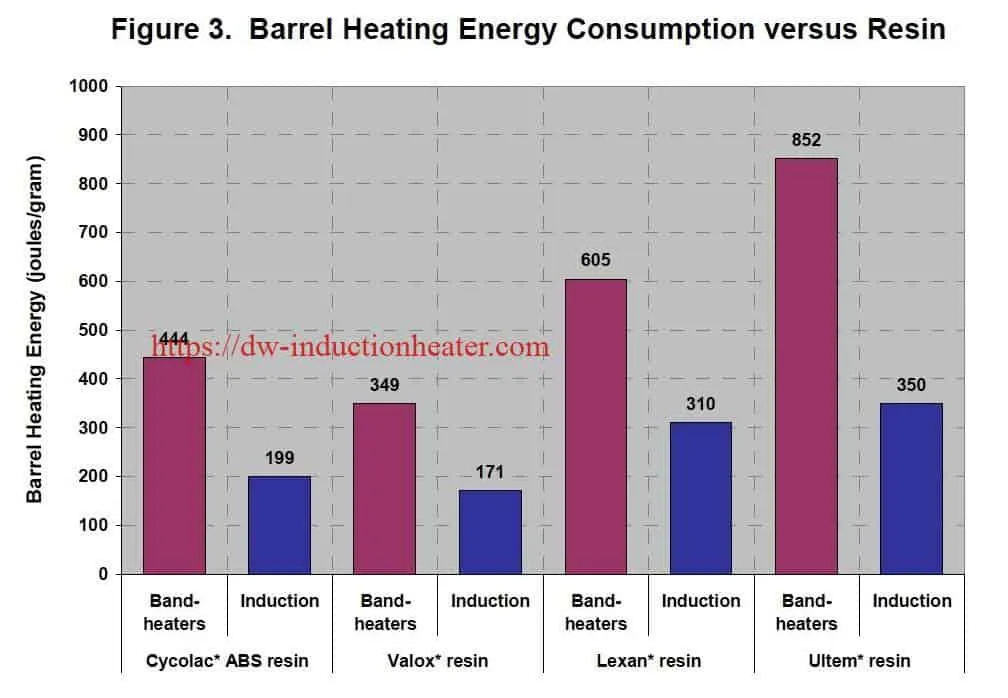

A halin yanzu, injinan sarrafa filastik galibi suna amfani da abubuwan dumama juriya waɗanda zasu iya haifar da babban adadin zafi da ke haskakawa a kewaye. Induction dumama shine manufa madadin magance wannan batu. Yanayin zafin jiki na induction dumama na'ura yana tsakanin 50ºC da 90ºC, ana rage asarar zafi sosai, yana samar da tanadin makamashi na 30%-85%. Sakamakon ceton makamashi ya fi bayyana a fili lokacin da ake amfani da tsarin dumama shigar da wutar lantarki.

Safety

Safety

Yin amfani da tsarin dumama shigarwa yana ba da damar saman injin ya kasance mai aminci don taɓawa, kuma hakan yana nufin zai iya guje wa raunin ƙonawa waɗanda galibi ke faruwa a cikin injin filastik waɗanda ke amfani da abubuwan dumama juriya, samar da amintaccen wurin aiki ga masu aiki.- Saurin dumama, ingantaccen aikin dumama

Idan aka kwatanta da dumama juriya wanda ingancin canjin makamashi ya kai kusan kashi 60%, dumama shigar ya wuce 98% inganci wajen canza wutar lantarki zuwa zafi. - Ƙananan zafin jiki na wurin aiki, mafi girman jin daɗin aiki

Bayan amfani da induction dumama tsarin, zafin jiki na gabaɗayan aikin samarwa yana raguwa da fiye da digiri 5. - Long rayuwar sabis

Ya bambanta da juriya na abubuwan dumama waɗanda ke da aiki mai dorewa a babban zafin jiki, dumama shigarwa yana aiki a kusa da zafin yanayi, don haka ingantaccen tsawaita rayuwar sabis. - Madaidaicin sarrafa zafin jiki, ƙimar cancantar samfur mai girma

Dumamar shigar da ƙara yana ba da ƙarancin ƙarancin zafi ko rashin ƙarancin zafi, ta yadda ba zai haifar da wuce gona da iri ba. Kuma zafin jiki na iya zama a saita ƙimar bambancin digiri 0.5.

Menene fifikon shigar da dumama filastik granulator / filasta extrusion idan aka kwatanta da dumama na gargajiya?

Menene fifikon shigar da dumama filastik granulator / filasta extrusion idan aka kwatanta da dumama na gargajiya?

| Induction hita | Na gargajiya dumama | |

| Hanyar mai zafi | Dumamar shigar da wutar lantarki shine tsarin dumama abu mai sarrafa wutar lantarki (yawanci karfe) ta hanyar shigar da wutar lantarki, inda ake samar da igiyoyin ruwa a cikin karfen kuma juriya ya kai ga dumama karfen Joule. Nadar shigar da kanta baya yin zafi. Abun da ke haifar da zafi shine abu mai zafi da kansa | Wayoyin juriya suna zafi kai tsaye kuma ana canja wurin zafi ta hanyar sadarwa. |

| lokacin dumama | Mai saurin dumama, inganci mafi girma | a hankali dumama-up, m yadda ya dace |

| Yawan ceton makamashi |

Ajiye 30-80% kuzarin kuzari, rage zafin aiki |

Ba za a iya ajiye makamashi ba |

| Installation | Easy shigar | Easy shigar |

| Operation | Mai sauƙin aiki | Mai sauƙin aiki |

| Maintenance |

Akwatin sarrafawa yana da sauƙi don maye gurbin ba tare da kashe injin ku ba |

Sauƙi don musanya amma dole ku kashe injin ku |

| Kula da Zazzabi | Ƙananan rashin ƙarfi na thermal da madaidaicin sarrafa zafin jiki saboda mai zafi baya yin zafi da kansa. | Babban rashin ƙarfi na thermal, ƙarancin daidaito a cikin sarrafa zafin jiki |

| Ingancin Samfuri | Mafi girman ingancin samfur saboda madaidaicin sarrafa zafin jiki | Ƙananan ingancin samfur |

| Safety |

Kube na waje yana da aminci don taɓawa, ƙananan zafin jiki, babu ruwan wutan lantarki. |

Zazzabi akan kube na waje ya fi girma, mai sauƙin ƙonewa. Yayyo wutar lantarki ƙarƙashin aiki mara kyau. |

| Rayuwar sabis na hita | 2-4years | 1-2 shekaru |

| Rayuwar sabis na Barrel da Screw |

Tsawon rayuwar amfani ga ganga, dunƙule da dai sauransu saboda ƙananan mitar canza dumama. |

Gajeren rayuwar amfani ga ganga, dunƙule da dai sauransu. |

| muhalli | Ƙananan yanayin yanayi; Babu hayaniya |

Yawan zafin jiki mafi girma da yawan hayaniya |

Ƙididdiga Ƙarfin Ƙarfin Ƙarfafawa

Game da sanin ikon dumama tsarin dumama data kasance, zaɓin ƙarfin da ya dace bisa ga ƙimar kaya

- Load rate ≤ 60%, m ikon ne 80% na asali ikon;

- Adadin kaya tsakanin 60% -80%, zaɓi ikon asali;

- Adadin kaya> 80%, ikon aiki shine 120% na asalin ikon;

Lokacin da dumama ikon data kasance dumama tsarin ba a sani ba

- Don injin gyare-gyaren allura, na'urar fim da aka busa da injin extrusion, ya kamata a lissafta ikon kamar 3W a kowace cm2 bisa ga ainihin yanayin silinda (ganga);

- Domin bushe yanke pelletizing inji, da ikon ya kamata a lissafta kamar 4W da cm2 bisa ga ainihin surface yankin na Silinda (ganga);

- Domin rigar yanke pelletizing inji, da ikon ya kamata a lissafta kamar yadda 8W da cm2 bisa ga ainihin surface yankin na Silinda (ganga);

Misali: Silinda diamita 160mm, tsawon 1000mm (watau 160mm=16cm, 1000mm=100cm)

Ƙididdigar yanki na Silinda: 16*3.14*100=5024cm²

Ana ƙididdigewa azaman 3W a cikin cm2: 5024*3=15072W, watau 15kW