Molding Injection Plastics tare da Induction Heating Machine

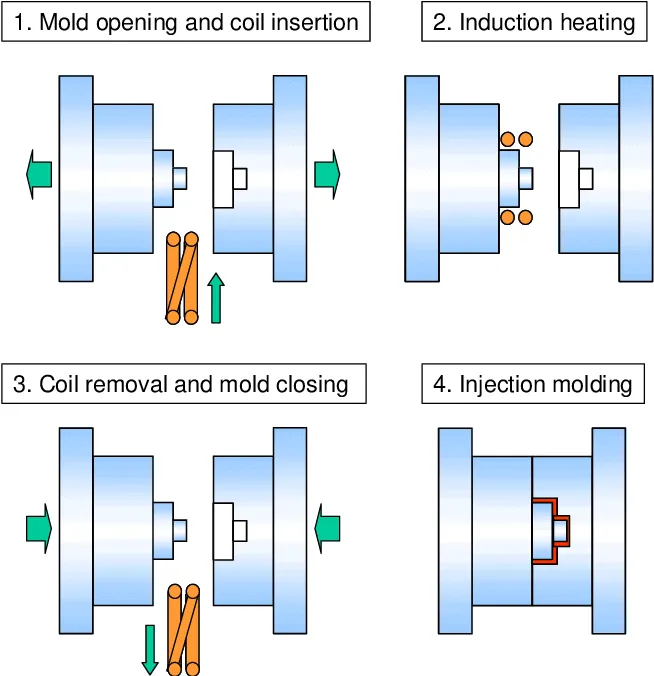

Roba Allura gyare-gyaren da shigar da dumama yana buƙatar pre-dumama na kyawon zafin zuwa mafi yawan zafin jiki, don tabbatar da magudanar da ta dace ko warkewar kayan allurar da aka ƙera. Hankula hanyoyin dumama da ake amfani dasu a masana'antar sune tururi ko ƙyama mai tsayayya, amma suna da rikici, basu iya aiki ba, kuma basu da aminci. Heatingarfin zafin jiki abu ne mai tsabta, mai sauri da ingantaccen makamashi wanda aka yi amfani dashi ko'ina a cikin recentan shekarun nan don maye gurbin tururi, gas ko kuma ƙwanƙwasa ƙwanƙwasawa da mutu.

Menene Allura Molding?

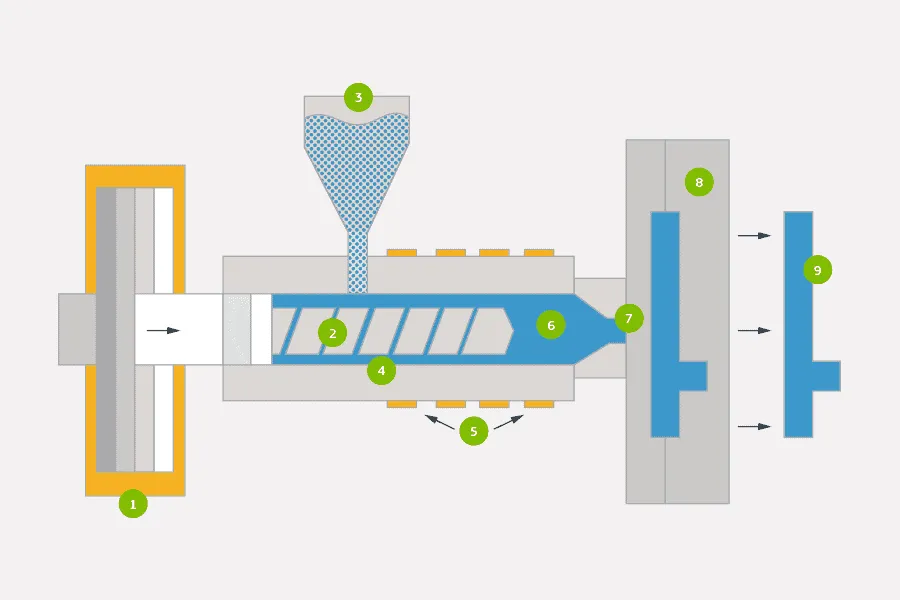

Gyaran allurar filastik tare da dumama wuta shine tsarin narkar da pellets na roba (thermosetting / thermoplastic polymers) wanda da zarar ya iya zama mai sauki, ana masa allura a matsin lamba a cikin ramin mould, wanda ya cika kuma ya karfafa don samar da samfurin ƙarshe.

Ta yaya Filashin Allura Molding yake Aiki?

Ta yaya Filashin Allura Molding yake Aiki?

Tsarin gyare-gyaren allurar filastik a Protolabs tsari ne na yau da kullun wanda ya shafi zanen aluminum. Aluminium yana canja wurin zafi sosai fiye da karfe, don haka baya buƙatar tashoshin sanyaya - wanda ke nufin lokacin da muka adana akan sanyaya ana iya amfani dashi don saka idanu akan matsin cika, damuwa na kwalliya da samar da yanki mai inganci.

Ana lodin ƙyallen maɓuɓɓuka a cikin ganga inda daga ƙarshe za a narkar da shi, a matse shi, sannan a yi masa allura a cikin tsarin masu gudu. Ana harba resin mai zafi a cikin ramin ƙwanƙwasa ta ƙofofin kuma ɓangaren an tsara shi. Ejector fil ya sauƙaƙa cire ɓangaren daga sifar inda ya faɗi cikin kwandon ɗorawa. Lokacin da aka kammala aikin, ana yin bangarori (ko samfurin farko) ana yin dambe da aikawa jim kaɗan bayan haka.

Ta yaya ake amfani da Indarancin Indunƙasa a cikin Masarar Mutuwar Halitta?

- Uunƙwasa Preheating na kayan aikin da kyawon tsaruwa don gyaran allurar filastik

- Cutar kayan aikin gyare-gyare don maganin kayan roba da tayoyin mota

- Mutuwar shigar da wuta don kitsen catheter da masana'antar kayayyakin kiwon lafiya

- Mutu da platen dumama don karfe stamping da forming

- Uunƙwasa Preheating na simintin gyare-gyaren masana'antar masana'antar ƙarfe

- Uunƙwasa atarfin zafi mai zafi da taurin hatimi da kayan naushi da mutu