Don ƙara yawan aiki da kuma rage tasirin zafi na dumama karfe, da shigar da brazing ana ba da shawarar fasaha. Amfanin wannan fasaha ya ƙunshi musamman a ainihin wurin dumama da aka kawo zuwa ga haɗin gwiwa. Dangane da sakamakon kwaikwaiyon lambobi sannan zai yiwu a tsara sigogin da suka wajaba don cimma yanayin zafi na brazing a lokacin da ake so. Manufar ita ce rage wannan lokacin don guje wa tasirin zafi da ba a so a kan karafa yayin haɗuwa da ƙarfe..Sakamakon simintin ƙididdigewa ya bayyana cewa haɓaka mitar na yanzu ya haifar da ƙaddamar da matsakaicin yanayin zafi a saman wuraren da aka haɗa karafa. Tare da haɓaka halin yanzu, an lura da raguwar lokacin da ake buƙata don isa ga zafin brazing.

Fa'idodin induction brazing na aluminum vs. tocili ko brazing na harshen wuta

Ƙarƙashin narkewar ƙananan ƙarfe na aluminum tushe tare da kunkuntar tagar tsarin zafin jiki na kayan aikin braze da aka yi amfani da shi yana da ƙalubale lokacin da ake kunna wutan lantarki. Rashin canjin launi yayin dumama aluminum baya samar da masu aikin braze duk wata alama ta gani cewa aluminium ya kai madaidaicin zafin brazing. Ma'aikatan Braze suna gabatar da adadin masu canji lokacin da ake kunna brazing. Daga cikin waɗannan sun haɗa da saitunan wutar lantarki da nau'in harshen wuta; nisa daga tocila zuwa sassan da ake murƙushewa; wurin da harshen wuta ya danganta da sassan da ake haɗawa; da sauransu.

Dalilan yin la'akari da amfani shigar da dumama A lokacin da brazing aluminum hada da:

- Mai sauri, saurin dumama

- Sarrafa, daidaitaccen sarrafa zafi

- Zafi (na gida) zafi

- Samar da layin daidaitawa da haɗin kai

- Ingantacciyar rayuwa mai daidaitawa da sauƙi

- Maimaituwa, abin dogara brazed gidajen abinci

- Inganta aminci

Nasarar shigar da brazing na kayan aikin aluminium ya dogara sosai kan ƙira induction coils don mayar da hankali ga makamashin zafi na lantarki a cikin wuraren da za a yi brazed da kuma dumama su daidai gwargwado ta yadda gariyar braze ta narke da gudana yadda ya kamata. Ƙirar shigar da ba ta dace ba na iya haifar da wasu wuraren da za su yi zafi sosai kuma wasu wuraren ba su sami isasshen ƙarfin zafi wanda ke haifar da haɗin gwiwa na braze da bai cika ba.

Don haɗin haɗin bututun alumini mai ƙyalli na yau da kullun, ma'aikaci yana girka zoben braze na aluminum, sau da yawa yana ɗauke da juzu'i, akan bututun aluminium kuma yana saka wannan cikin wani bututu mai faɗaɗa ko abin da ya dace. Ana sanya sassan a cikin coil induction kuma a yi zafi. A cikin tsari na yau da kullun, ƙarfen filler ɗin braze yana narkewa kuma yana gudana cikin haɗin haɗin gwiwa saboda aikin capillary.

Me yasa induction braze vs. Torch braze aluminum components?

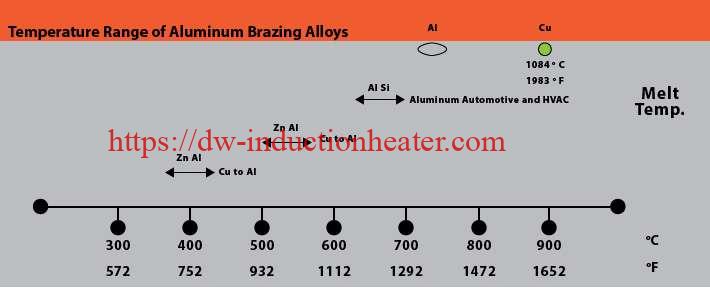

Na farko, ɗan ƙaramin bango akan gawawwakin aluminium na gama gari wanda ke yaɗu a yau da na gama-gari na aluminum da masu siyar da ake amfani da su don haɗawa. Abubuwan haɗin aluminum na brazing sun fi ƙalubale fiye da abubuwan haɗin jan ƙarfe na brazing. Copper yana narkewa a 1980 ° F (1083 ° C) kuma yana canza launi yayin da ake zafi. Aluminum alloys galibi ana amfani da su a cikin tsarin HVAC suna fara narkewa a kusan 1190°F (643°C) kuma ba sa samar da wasu alamu na gani, kamar canza launi, yayin da yake zafi.

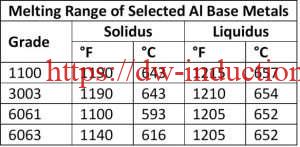

Ana buƙatar madaidaicin sarrafa zafin jiki azaman bambanci a cikin narkewa da yanayin zafi na aluminium, ya dogara da ƙarfen tushe na aluminium, ƙarfen filler braze, da tarin abubuwan da za'a yi brazed. Misali, Bambancin zafin jiki tsakanin solidus zafin jiki na biyu gama gari na aluminum gami, 3003 jerin aluminum, da kuma 6061 jerin aluminum, da ruwa ta zafin jiki na akai-akai amfani da BAlSi-4 braze gami ne 20 ° F – wani kunkuntar tsarin zafin jiki taga, don haka larura. daidai iko. Zaɓin kayan kwalliyar tushe yana da mahimmancin gaske tare da tsarin aluminum waɗanda ake murƙushewa. Mafi kyawun aiki shine a yi braze a yanayin zafin da ke ƙasa da ƙaƙƙarfan zafin gami da kayan aikin da ake haɗa su tare.

| AWS A5.8 Rarraba | Haɗin Kan Sinanci | Solidus °F (°C) | Liquidus °F(°C) | Yanayin zafin jiki |

| BAISI-3 | 86% Al 10% Si 4% Cu | 970 (521) | 1085 (855) | 1085 ~ 1120 °F |

| BAISI-4 | 88% aL 12% Si | 1070 (577) | 1080 (582) | 1080 ~ 1120 °F |

| 78 Zn 22% Al | 826 (441) | 905 (471) | 905 ~ 950 °F | |

| 98% Zn 2% Al | 715 (379) | 725 (385) | 725 ~ 765 °F |

Ya kamata a lura cewa lalata galvanic zai iya faruwa tsakanin wuraren da ke da zinc da aluminum. Kamar yadda aka gani a cikin ginshiƙi na galvanic a Hoto na 1, zinc ba shi da daraja kuma yana ƙoƙarin zama anodic idan aka kwatanta da aluminum. Ƙananan bambancin yuwuwar, ƙananan ƙimar lalata. Bambanci mai yuwuwa tsakanin zinc da aluminum yana da ɗan ƙaranci idan aka kwatanta da yuwuwar tsakanin aluminium da jan ƙarfe.

Wani abin al'ajabi lokacin da aluminum aka brazed tare da zinc gami yana pitting. Tantanin halitta na gida ko lalatawar rami na iya faruwa akan kowane ƙarfe. Aluminum yawanci ana kiyaye shi ta wani fim mai ƙarfi, sirara wanda ke fitowa a saman lokacin da aka fallasa su zuwa iskar oxygen (aluminum oxide) amma lokacin da ruwa ya cire wannan Layer oxide mai kariya, rushewar aluminum na iya faruwa. Yayin da karfen filler ya dade yana zama narkakkar, mafi tsananin narkar da shi.

Aluminum yana ƙirƙirar Layer oxide mai tauri yayin brazing, don haka amfani da juzu'i yana da mahimmanci. Za'a iya yin abubuwan haɗin aluminum masu jujjuyawa daban kafin brazing ko kuma ana iya shigar da alloy brazing alloy mai ɗauke da juzu'i cikin tsarin brazing. Dangane da nau'in juzu'in da aka yi amfani da shi (lalata vs. mara lalacewa), ana iya buƙatar ƙarin mataki idan an cire ragowar juzu'in bayan brazing. Tuntuɓi mai sana'anta brazing da gyare-gyare don samun shawarwari akan gami da brazing gami da juzu'i dangane da kayan da ake haɗawa da yanayin zafi na brazing.